Almost every week another company releases a brainchild born from a new 3-D printing technology: biodegradable and bionic artificial bone structures to printing chemical reactions with the chemputer. Here are a few interesting materials on the market now:

Printing with Wood

Start with James Novak’s wooden 3-D printed smartphone amplifier, Ferdinand Jahnke’s printed crate and Odette Coutant’s Tree Napkin Ring. Wood has always been exemplary for product and furniture design. The Asit chair by Drawn expresses wood fibers with a twist thanks to 3-D printing.

Beyond manipulating form, interlocking parts of product design can be done with 3-D printed wood objects. Lucas Alousis created his Teeny Tiny Treasure Chest that portrays a fully-functional box that opens and closes, all 3-D printed. Designers can now play with hollowing out the objects when using wood as well. Tommy Rombauts presents a little bonhomme called Tomy Tones, a prime example.

Molten Glass

Designer Neri Oxman’s group Mediated Matter pours glass like honey with the 3-D printer G3DP, a product in collaboration with MIT’s Department of Mechanical Engineering and MIT’s Glass Lab. The machine’s ceramic nozzle extrudes the liquid glass, producing the “first of its kind” optically transparent 3-D printed glass.

Molten glass beads are loaded into the top of a 1,800-watt crucible kiln chamber, which measures 250 x 250 x 300 mm (9.8 x 9.8 x 11.8 in) and thus limits the size of printed objects. The chamber contains a transparent ceramic window used to observe and monitor.

Salt & Sand

Design tank Emerging Objects use their salt polymer creation called ‘saltygloo’ to 3-D print structures. Salthouse, piloted by Emerging Objects and Rael San Fratello, illustrates geometric segments with eyelets that allow natural light to radiate areas of the interior, creating a soft atmosphere.

Similar in texture, sand presents another environmentally sound option. Desamenara, an architecture firm based in Italy, 3-D prints monumental structures in sand using the D-shape printer, released in 2008. The printer uses a stereolithography process, which stacks sand and an inorganic binder layer by layer to fabricate forms. The company is currently using the D-shape to forge artificial coral reefs, preserving beaches from energetic sea waves.

Shiro Studio from London also used the D-shape printer to create Radiolaria, a large pavilion made of artificial sand-stone material without steel reinforcement. Some machines that print with materials such as polymers, sand, metal and plaster are S-Print, M-print, ZPrinter and Voxeljet.

Courtesy of Emerging Objects

Plastics

Plastic “soups” are used to create toys, architectural models and prosthetics. Redectec’s Protocycler recycles diverse objects, from coffee cup lids to 3-D printed projects gone wrong, to create plastic filament turned into ‘ink’ for 3-D printing.

Gathering 3-D enthusiasts around the planet, Van der Kley assembled 4,760 thermoplastic printed pieces to construct Project Egg. The project was inspired by repetitive, organic patterns and measures 10 feet high. Catch it at Milan’s Salone Internazionale del Mobile in April 2016.

Photo: Courtesy of Michiel van der Kley, Project Egg exhibition in Eindhoven during Dutch Design Week 2014

Magnesium Oxide Cement (MOC)

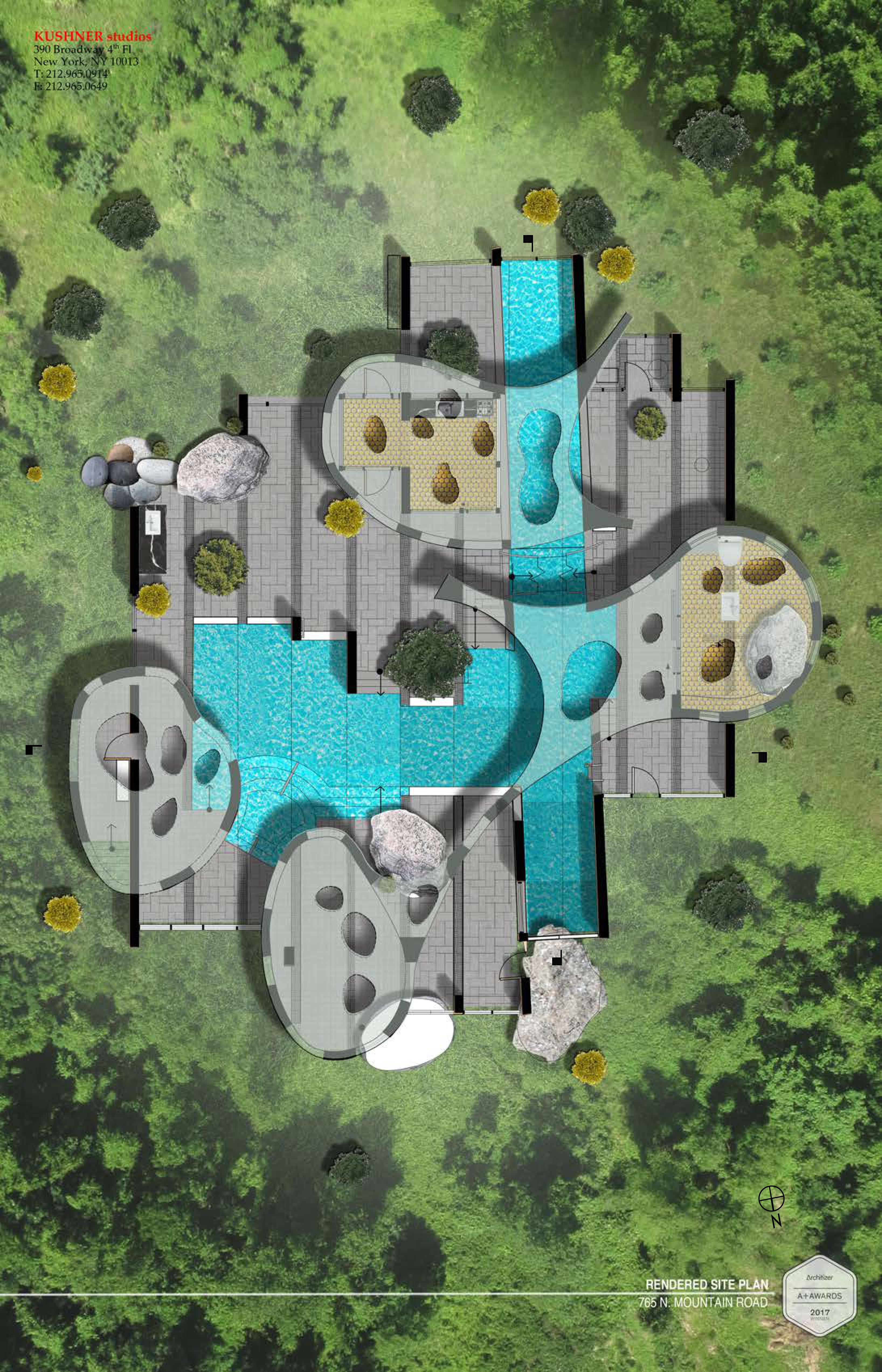

An alternative is Magnesium Oxide Cement (MOC), a form of concrete made up of sand, magnesium and the inclusion of saltwater that drips onto the composite. The material is found in Gardiner, New York. Adam Kushner of Kushner Studio’s in New York City will use this local material in his Mountain Road Pool project, a 3-D printed 225 square meter estate with a pool and pool house.

“MOC has not remained popular in the building industry because the magnesium oxychloride phase is not stable in prolonged contact with water, […] leaving magnesium hydroxide behind as the binder. Since magnesium hydroxide does not have adequate strength, the cement bond as a whole is severely weakened,” according to The Chemistry and Technology of Magnesia by Mark A. Shand.

The project is underway and while it seems a difficult task to use MOC for an entire estate, Kushner tells ArchiExpo e-Magazine, “Rock and soil? No challenges! It’s what is in every bag of stone concrete made on this planet.”

While Kushner admits MOC isn’t the strongest cement, he explains that it becomes stronger with the use of saltwater. Also, this one-story project doesn’t require anything above MOC strength. Still, a special formula is on the move, “our scientist Tom Brigham is experimenting with a new ad admixture. Stay tuned.”

Courtesy of Kushner Studio

Regolith!

In 2013 European Space Agency proved 3-D printing with lunar materials possible. A year later architect firm Foster + Partners drew up an outline where a fleet of robots 3-D prints a structure from regolith (mantle rock), a stimulant composed of soil and rock found on the surface of the moon. “Melter” robots would be used to fuse the regolith using microwaves, said to provide a protective coating from harsh environmental elements.

Water

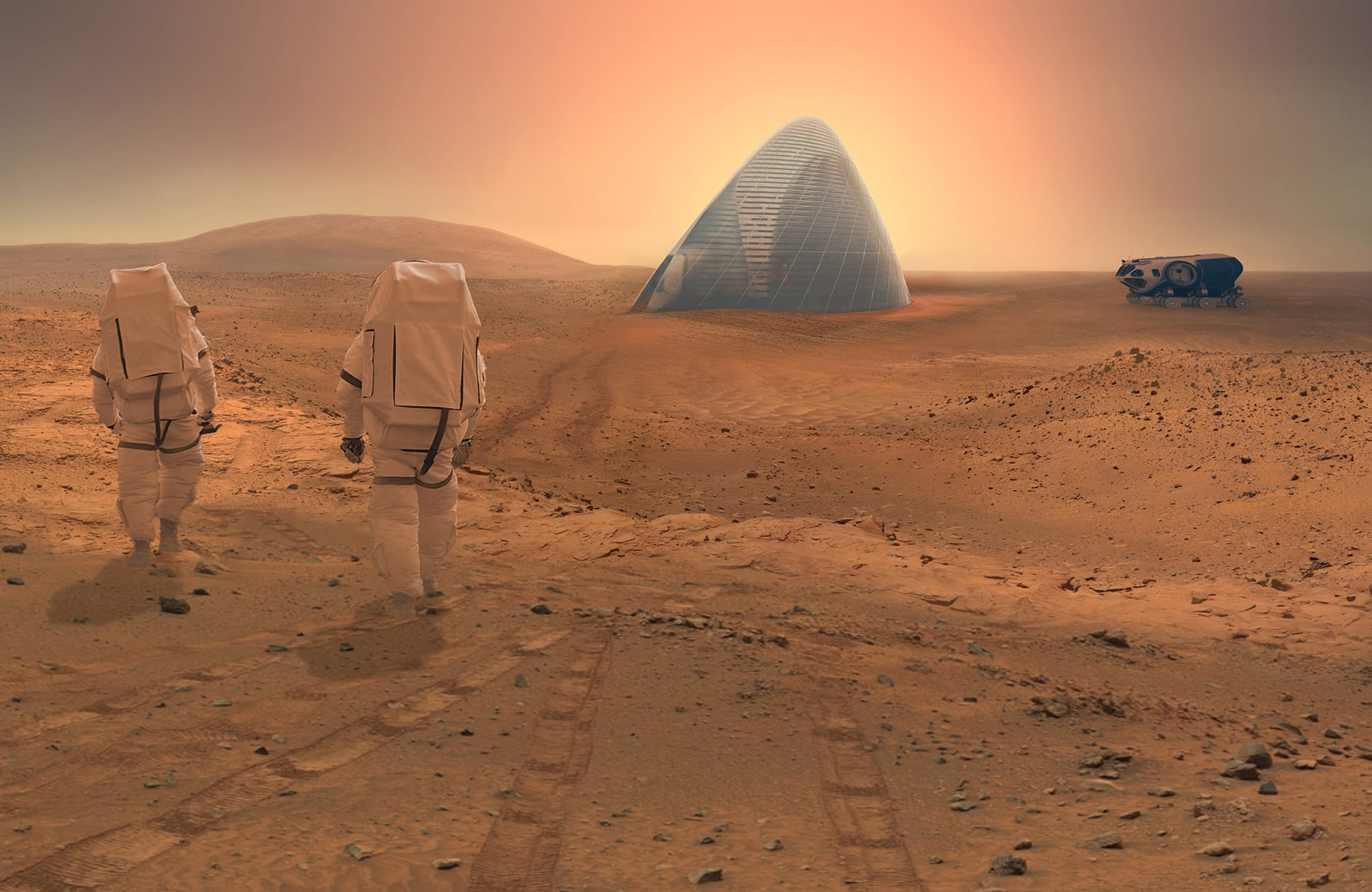

The 3-D Printed Habitat Challenge organized by America Makes and NASA was launched in May 2015 to build on Mars with a result of 30 finalists. Team Space Exploration Architecture and Clouds Architecture Office with the ICE HOUSE earned first prize with their notable Martian igloo. The Ice House relies on water to serve as the main construction component for the structure. The evidence of water on Mars and consistently cold surface temperatures in the planet’s northern hemisphere make this ideal. The igloo uses a unique 3-D printing technique, playing with the physics of water.

MARS ICE HOUSE. Courtesy of Clouds Architecture Office.

Coming Up

Designers such as Chloè Rutzerveld with her “Edible Growth” project are showing just how far we can go with 3-D printing. Now moving beyond this, companies such as carbon3d with its CLIP technology (Continuous Liquid Interface Production), demonstrate 4-D printing that changes the shape of 3-D printed objects in response to heat, air and water. Professor Marc inhet Panhuis at the University of Australia is printing with a hydrogel that reduces to nearly half its size when in contact with liquid at 35° C (95° F). By printing heat sensitive valves, this breakthrough could prevent catastrophes such as floods and saves lives by opening bronchial airways in the human body.