The 2025 edition of Big 5 Global highlighted a new era for construction innovation—one defined by decarbonization, circular materials, and data-driven design. As the industry faces mounting pressure to reduce emissions and operate more sustainably, leading companies unveiled solutions that rethink everything from early-stage planning to material selection. Two standout innovations-AECOM’s ScopeX platform and Bekaert’s Dramix® Loop recycled steel fiber- demonstrate how sustainability is no longer a secondary objective but a primary driver of engineering progress. They showcase how the sector can pair high performance with environmental responsibility, shaping a more climate-resilient built environment.

Complementing these material and environmental advances, Meter Technology introduced an AI-powered surveying and engineering platform capable of compressing weeks of work into mere days, highlighting how digital intelligence is becoming just as crucial as low-carbon solutions. These innovations reflect a sector moving rapidly toward smarter, cleaner, and more efficient construction.

AECOM ScopeX: A Data-Driven Blueprint for Decarbonizing the Built Environment

AECOM’s ScopeX is a comprehensive decarbonization framework that embeds carbon reduction into every phase of the project lifecycle; from planning and design to construction and operation. Combining standard industry tools with custom carbon-accounting and modeling systems, ScopeX enables teams to simulate scenarios, optimize designs, and identify the lowest-carbon solutions early on. Backed by science-based emissions targets, the platform uses verified global data to support informed decision-making and guides stakeholders such as engineers, clients, contractors and suppliers, toward practical carbon-saving strategies.

Real-world examples, such as redesigning infrastructure components to reduce steel and concrete demand or substituting low-carbon materials like GGBS, illustrate its impact. Already tested on major projects, including COP28, ScopeX shows how integrating validated data with collaborative design can meaningfully accelerate decarbonization across the construction sector.

Dramix® Loop: Circular Steel Fibers Turning Tire Waste Into High-Performance Reinforcement

Dramix® Loop repurposes the high-strength steel cords found in end-of-life tires to create a fully circular steel-fiber reinforcement for concrete. The product transforms a global waste stream into a low-carbon, high-performance construction material with an exceptionally low environmental footprint. Each kilogram contains up to 120,000 fibers that create a dense internal reinforcement network, improving crack control, ductility, and post-crack performance.

Available in multiple lengths (15–25 mm), the fibers can be adapted to a wide range of applications including slabs, tunnels, raft foundations, infrastructure, and precast elements. Lighter and more durable than traditional steel bars and resistant to corrosion- Dramix® Loop enhances structural reliability while simplifying logistics. Ultimately, it represents a shift toward circular materials that deliver both environmental benefits and superior engineering performance.

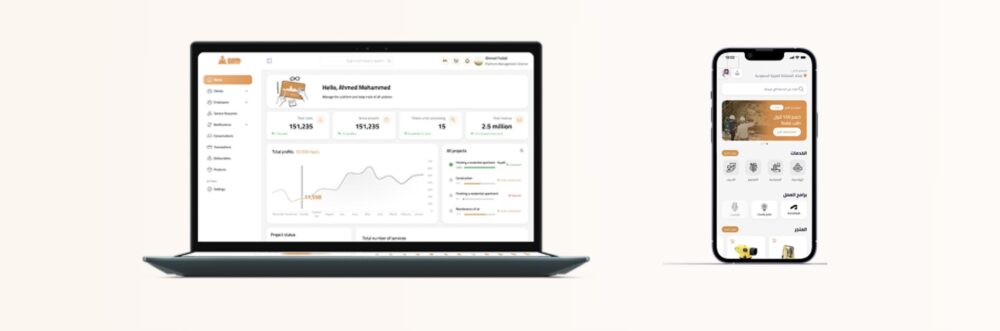

Meter Technology: AI-Powered Precision for Faster Engineering

Meter Technology introduced an AI-driven platform that streamlines surveying and engineering workflows, addressing long-standing inefficiencies in early project planning. The system integrates high-precision digital surveying with automated modeling and verification tools, allowing project teams to generate accurate engineering outputs within a single environment.

According to the company, tasks that previously took weeks can now be completed in as little as 48 hours.

The platform’s ability to standardize data across multiple countries ensures consistent quality and reduces discrepancies between design intentions and site conditions. This not only minimizes rework but enhances decision-making and project predictability. By reducing the need for repeated site visits and limiting material waste caused by measurement errors, Meter also supports more sustainable construction practices.