Etex is advancing sustainable construction through innovative plasterboard manufacturing, recycling initiatives at its Mazan quarry, and the introduction of 100% recycled gypsum boards.

With a growing demand for eco-friendly and sustainable construction materials, Etex is driving the industry forward through a combination of cutting-edge plasterboard manufacturing, innovative R&D, and the development of new products to meet global needs. We recently had the opportunity to attend a press tour of Etex’s Bristol factory in the UK and key sites in France, where the company showcased its modular construction solutions, plasterboard innovations, and commitment to sustainability.

Since the grand opening of the Bristol factory mid March, we dive into the most exciting developments at Etex. This includes their new 100% recycled plasterboard and high-tech solutions that are set to transform the construction landscape.

The Bristol Factory: Leading Plasterboard Manufacturing with High-Speed Innovation

At the forefront of Etex’s plasterboard production is its new Bristol factory, which houses one of Europe’s most efficient production lines. This facility is a key driver of Etex’s Building Performance division, producing Siniat plasterboards with an impressive focus on sustainability. The high-speed production line allows Etex to integrate up to 30% recycled gypsum into its products, exceeding industry standards.

Jochen Friedrichs, head of Etex’s Building Performance division, spoke to us about the factory’s recycling leadership:

“Here in the UK, especially at our Bristol plant, we’ve mastered recycling—integrating 30% recycled gypsum into every plasterboard we make. We even reach up to 40% in some of our other plants, far better than our competitors.”

This emphasis on sustainability is part of Etex’s CarbonShift program, which aims to significantly reduce CO₂ emissions by optimizing energy use in their manufacturing processes, including advanced heat recovery systems. The company currently has two patents to advance its heating technology.

The Bristol facility also plays a key role in minimizing environmental impact by sourcing recycled gypsum from production waste, demolition sites, and take-back programs from construction projects. As Friedrichs explained:

“What’s exciting is, just this week, we patented a product with 100% recycled gypsum and nearly 100% recycled materials overall. This innovation is paving the way for a truly sustainable future in construction.”

While this new board will be exclusively produced in France, the company aims to spread the manufacturing of the board to factories in other countries.

Regarding the UK, Etex was the first UK plasterboard manufacturer to receive third-party certification for recycled content. Their Siniat Universal Board™ contains at least 27% post-consumer recycled gypsum. This certification reflects Etex’s ongoing dedication to the circular economy, driving the use of recycled materials in its plasterboard production.

Etex France: Manufacturing the Future of Recycled Plasterboards

France, Etex’s largest market, accounting for 20% of the company’s global revenues, is set to play a pivotal role in the production of Etex’s 100% recycled plasterboard. This groundbreaking product will first be manufactured at Etex’s French plants, with plans to expand production to other regions.

The R&D pilot line in Carpentras, inaugurated in September 2022, was key to developing this new product. Eric Bertrand, Etex’s Innovation Director, highlighted the importance of the facility in advancing their plasterboard formulations:

“The pilot line allows us to push the boundaries of plasterboard production, testing new processes and materials without disrupting full-scale operations. The result is a product that not only meets performance standards but is also a leader in sustainability with 100% recycled gypsum content.”

The 100% recycled plasterboard will primarily target large-scale projects seeking eco-certifications. It underscores Etex’s commitment to circular economy practices and reducing its environmental impact.

Etex’s Mazan quarry, the largest open-cast gypsum quarry in France, also supports this initiative by integrating plasterboard waste recycling into its production process, reducing the need to extract 100,000 tonnes of gypsum annually. This focus on resource conservation and environmental restoration demonstrates Etex’s dedication to sustainable material sourcing.

“The more we recycle, the longer the quarry will last. This is part of our goal to create a circular economy that benefits both the environment and our business,” Vivien Bonnelles, Industrial Director, South East, Etex France BP, stated during our guided tour.

Etex’s Diverse Material Portfolio: More Than Just Plasterboards

While plasterboard innovation remains central to Etex’s Building Performance division, the company’s diverse portfolio extends beyond plasterboards to include fiber cement boards, fire protection materials, and high-performance insulation. Etex’s flagship brands, such as Promat, Cedral, URSA, and EQUITONE, provide a comprehensive suite of materials that cater to both interior and exterior applications.

As Eric Bertrand summarized during the press tour:

“Our focus is on providing versatile materials that meet the changing needs of the construction industry. From our acoustic plasterboards used in cinemas to our exterior Weather Defence™ panels, Etex is continually innovating to ensure the highest performance across different construction sectors.”

READ more about the latest products added to the Etex portfolio here.

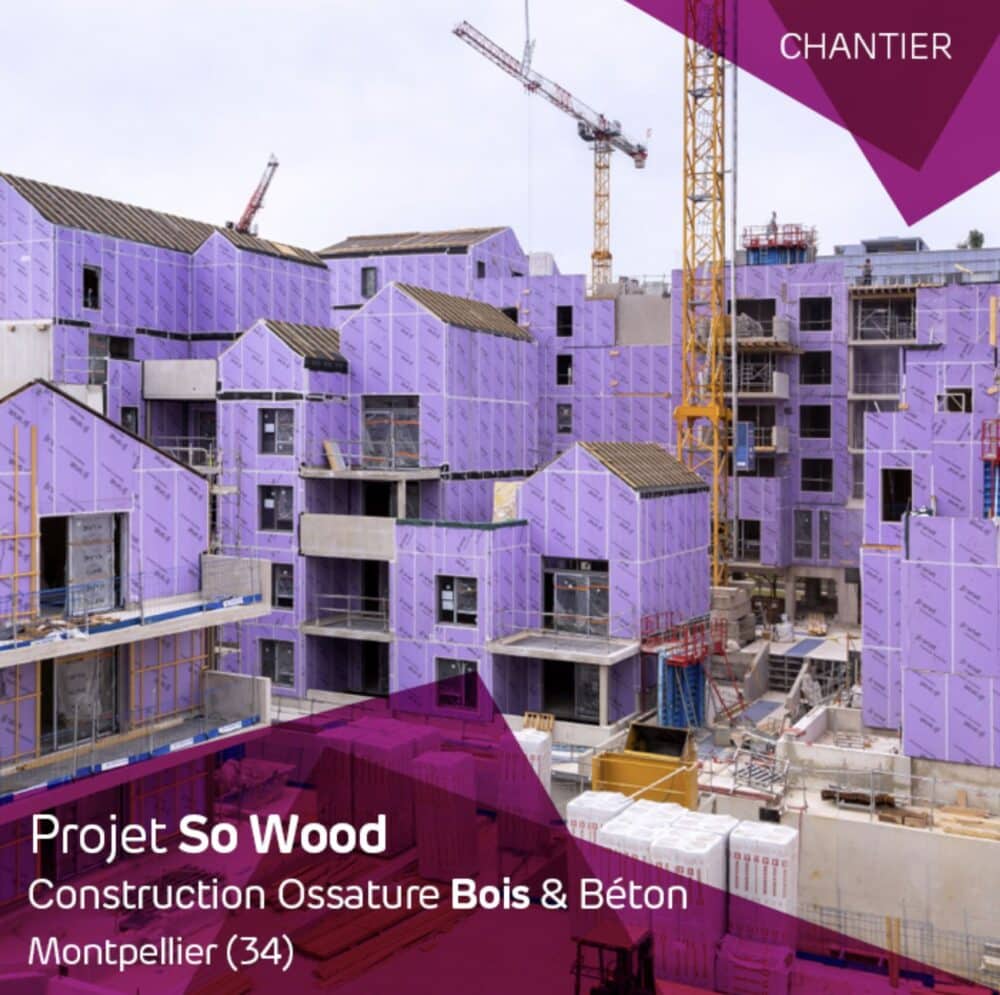

A prime example of Etex’s capabilities is the So Wood project in Montpellier, France, completed in 2024. This mixed-use complex utilized Etex’s Weather Defence™ board, a versatile product that combines weather resistance, fire protection, and durability, to meet the project’s high energy performance and acoustic standards. The success of So Wood illustrates how Etex’s diverse material solutions can be seamlessly integrated into modern building projects, reducing the carbon footprint while maintaining aesthetic and functional quality.

Modular Construction: The Future of Building with Etex’s Off-Site Solutions

Etex’s growing focus on off-site modular construction is perhaps one of its most exciting developments. By combining its extensive range of plasterboards, fire protection materials, insulation products, and fiber cement boards, Etex has created a platform of materials that enables fully modular building solutions. This approach not only reduces construction times but also minimizes waste and environmental impact.

Bernard Delvaux, CEO of Etex, discussed the company’s growing focus on modular solutions during the press conference, stating:

“We’re combining our expertise across multiple platforms to deliver complete systems that reduce costs, improve sustainability, and speed up the construction process. This is the future of the construction industry.”

With modular construction gaining momentum in markets such as the UK and France, Etex’s platform of pre-fabricated panels and modular systems is positioned to meet the demand for sustainable, high-quality buildings.

With its strong presence in plasterboard manufacturing, commitment to sustainability, and focus on modular construction, Etex is poised to lead the way in creating sustainable, high-performance building solutions for the future.

“At Etex, innovation is not just about developing new products—it’s about rethinking the entire construction process to make it more efficient, sustainable, and accessible for everyone,” Delavaux explained.

Etex continues to build on its legacy of high-performance building materials, combining sustainability and innovation to meet the evolving needs of the global construction industry.