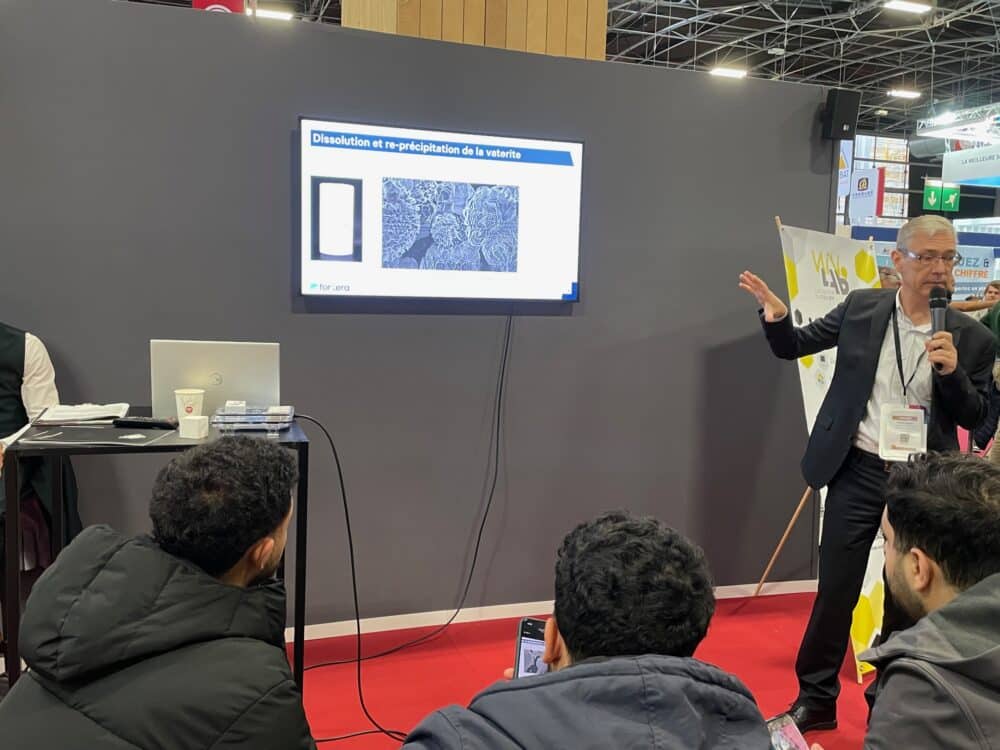

During the construction event Batimat, startup Fortera had the opportunity to present its low-carbon cement to industry professionals. Images and content gathered by our social media manager Emmanuelle Roux.

Fortera, a Franco-American startup, made a notable debut at the Batimat construction fair, unveiling its groundbreaking low-carbon cement, ReAct®. The company captivated attendees with its innovative solutions to reduce the environmental impact of cement production, a significant contributor to global CO2 emissions.

At the heart of Fortera’s offering is the ReAct® technology, a cement derived from calcium carbonate. Using a patented remineralization process, known as ReCarb®, Fortera’s cement reduces CO2 emissions by up to 70% compared to traditional Portland cement. The process produces two distinct products: ReAct® Pure and ReAct® Blend, both designed to dramatically lower the carbon footprint of concrete manufacturing.

Fortera’s Chief Manufacturing Officer, Keith Krugh, emphasized the company’s commitment to sustainability during the presentation:

“Fortera products can have 70% less embodied CO2 than Portland cement, zero embodied CO2, or even negative embodied CO2. And this process is being built at commercial scale now, cost-competitive with traditional cement.”

ReAct Pure & ReAct Blend: Strengthening Concrete

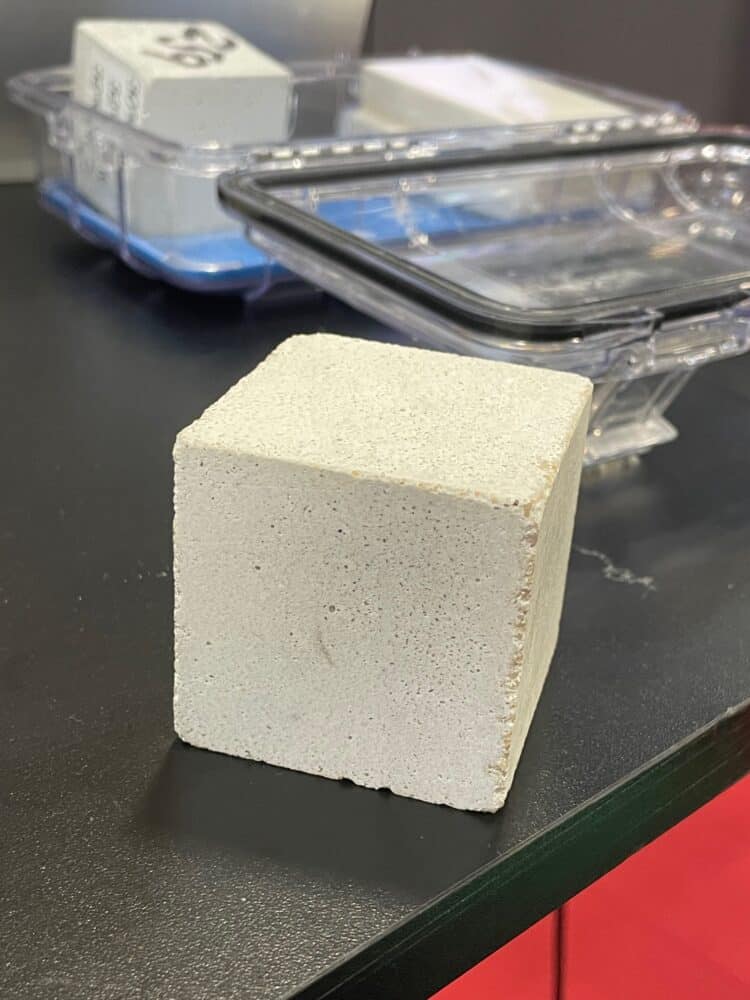

Fortera’s ReAct® Pure, a novel calcium carbonate cement, is poised to reduce emissions drastically for use in prefabrication and cement boards, while ReAct® Blend can be incorporated into Portland cement mixes to enhance both strength and sustainability. These innovations stem from Fortera’s process of dissolving and recalcifying calcium carbonate into stable polymorphs such as aragonite and calcite, providing strength comparable to conventional cement.

During the event, Fortera’s spokesperson walked the audience through the cement’s microstructure transformation. A captivating animated demonstration illustrated the product’s core process, highlighting the role of vaterite, a form of calcium carbonate, which dissolves and reprecipitates to form stronger aragonite crystals.

“These small balls are 5 or 6 microns, which are dissolving and recalcifying in the form of calcite. And this is what will give the concrete of 40 MPa, in terms of resistance, quite similar to what you can find everywhere,” explained the representative of Fortera during the demonstration.

This transformation contributes to the strength of the concrete, achieving up to 40 MPa in compressive strength, comparable to standard Portland cement.

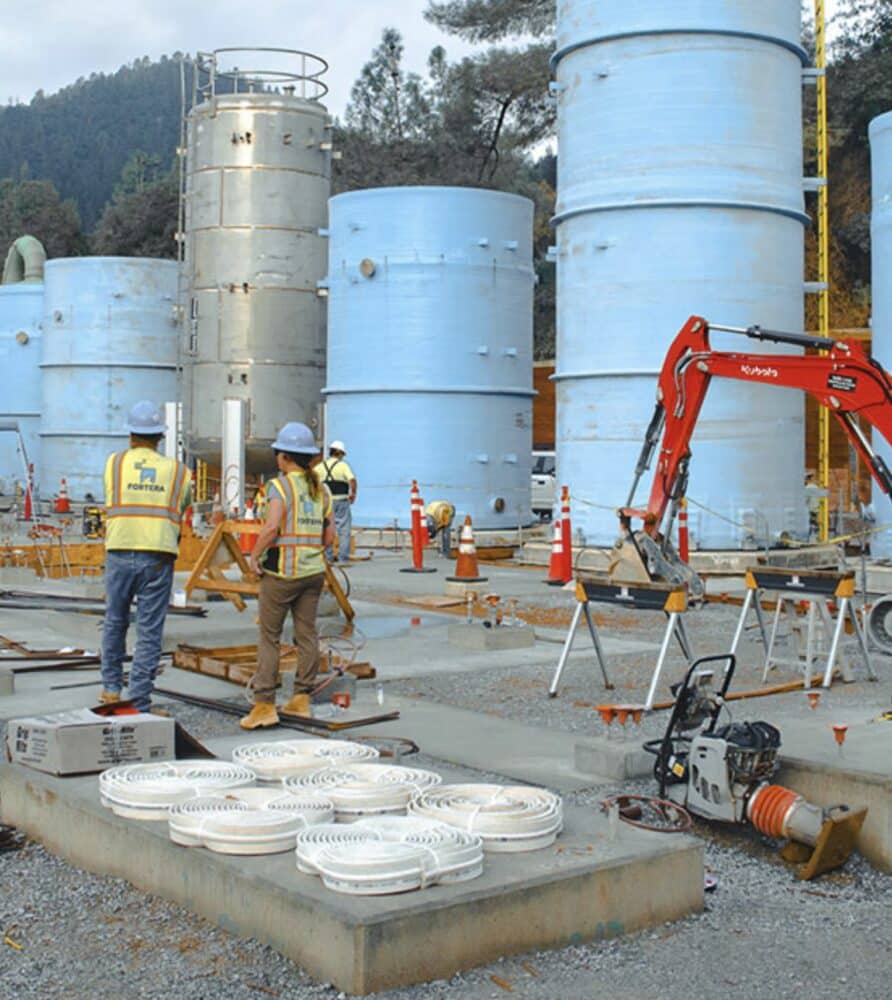

Global Expansion Plans

Fortera’s presence at Batimat comes on the heels of the startup’s expansion efforts. Having already established a factory in Redding, California, capable of producing 15,000 tons annually, Fortera plans to scale its operations. The company is on track to build a larger production facility with a capacity of 300,000 to 350,000 tons per year in North America and is eyeing the European market with plans to establish a factory within the next two years.

“We are working on how to build a factory in Europe, and propose this solution in Europe.”

The company’s innovations have earned it international recognition, winning the prestigious Net-Zero Industries Award 2023 in the U.S. for outstanding projects in the Mission Innovation category. Fortera’s success reflects the growing demand for sustainable solutions in the construction industry, especially in light of increasing global population and urbanization.

In-depth Study to Analyze Fortera’s Cement

A recent study on calcium carbonate cement highlights the mechanical properties and microstructural development of this novel material through polymorphic transformations. By examining the conversion of vaterite to aragonite and calcite, researchers found that the transformation to aragonite significantly enhances the cement’s strength. Using various techniques, such as X-ray diffraction (XRD), scanning electron microscopy (SEM), and synchrotron-based tools, the study demonstrated that aragonite interlocks in a way that calcite does not, contributing to its superior compressive strength.

The study compared two types of calcium carbonate cement (CcC): one that transforms into calcite and another into aragonite. When converted to aragonite, the cement displayed three times the strength of calcite, with aragonite forming an interpenetrating matrix that boosted the material’s resistance. This was particularly noteworthy at low densities, a significant advantage for applications requiring lightweight, yet durable, building materials.

The implications of these findings are substantial for sustainable construction. With cement being a major source of global CO2 emissions, this study underscores calcium carbonate cement’s potential to offer a greener alternative to Portland cement. By leveraging natural polymorph transformations, Fortera’s research showcases a material that not only reduces carbon footprint but also meets strength and durability demands.

Looking Ahead

Fortera’s low-carbon cement solutions are not just a response to climate change but also an economically viable alternative to traditional cements. The startup is already working on achieving further approvals within ASTM standards and European norms, preparing the ground for wider adoption in the industry.

As the company continues to build momentum, Fortera’s innovative cement technology offers hope for reducing the cement industry’s carbon footprint on a global scale. With commercial-scale production on the horizon and strong interest from industry stakeholders, Fortera is set to play a key role in shaping the future of sustainable construction.