Hempitecture is developing hemp-based, carbon-negative building materials that enhance thermal performance, indoor air quality, and environmental sustainability.

Need to run? Here are the main takeaways:

- Sustainable Innovation: Hempitecture develops cutting-edge, hemp-based building materials like HempWool®, PlantPanel X, and Hempcrete, which are carbon-negative, non-toxic, and enhance thermal and acoustic performance.

- Expansion and Impact: The company is rapidly growing with new manufacturing facilities and projects, reinforcing its commitment to decarbonizing the construction industry while supporting local economies.

In an era where environmental sustainability is becoming increasingly central to architectural design, Hempitecture has emerged as a pioneering force in the construction industry. Founded in 2013 and headquartered in Idaho, the company is dedicated to creating some of the most sustainable building materials available today. By harnessing the remarkable properties of industrial hemp—a fast-growing, carbon-sequestering plant—Hempitecture produces insulation and construction materials that address the urgent need to decarbonize the built environment.

The company’s innovative approach not only aligns with global sustainability goals but also supports domestic agriculture and local economies. Hempitecture sources its raw hemp fiber from U.S. farms, emphasizing a regional supply chain that reduces transportation emissions and supports rural agricultural communities. As a result, Hempitecture is not just innovating in terms of materials but also reshaping the way supply chains work within sustainable construction. With a commitment to healthy, high-performance, and carbon-negative building solutions, Hempitecture is helping architects, builders, and developers rethink how they approach modern construction.

HempWool®: A Revolution in Sustainable Insulation

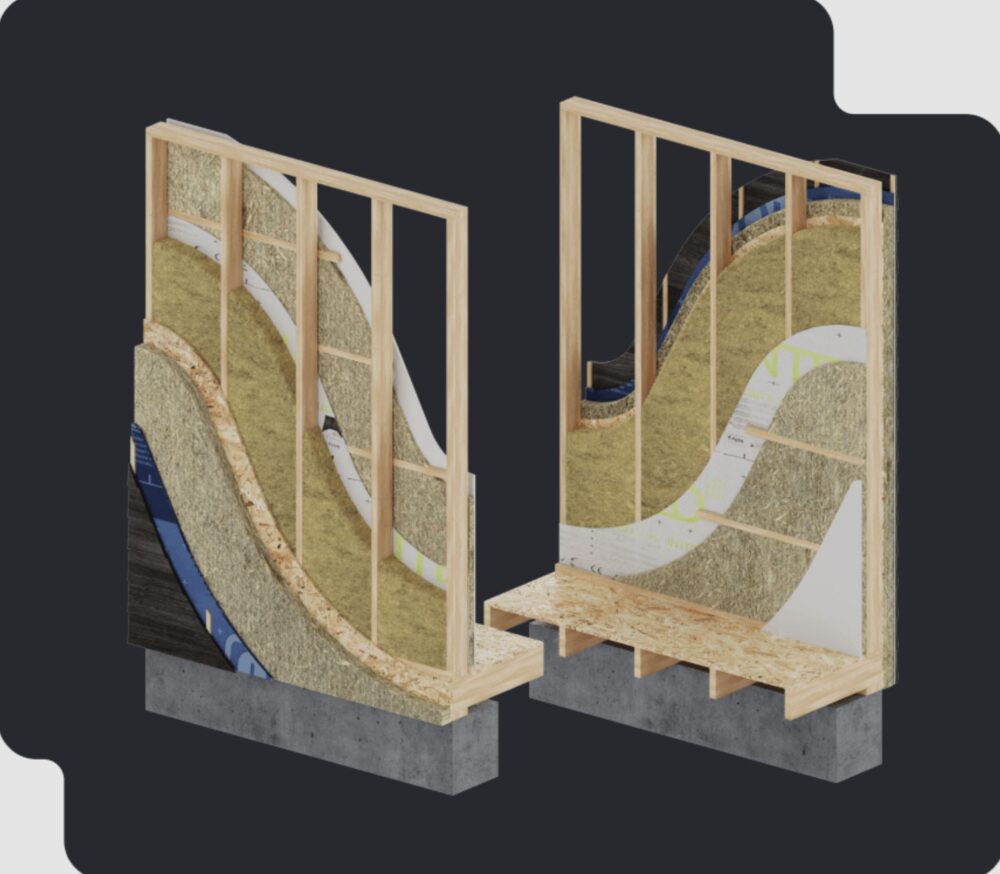

One of Hempitecture’s flagship products, HempWool®, is redefining what insulation can be, offering both thermal and acoustic performance without compromising on health or sustainability. Unlike conventional insulation materials like fiberglass, mineral wool, or foam-based products, HempWool is made from 90% natural hemp fiber combined with a non-toxic binder. This composition not only makes it safe to touch—a crucial consideration for installers and end-users alike—but also ensures that the material remains VOC-free and non-irritating.

HempWool is designed to maintain structural integrity within framing systems, thanks to its pressure-fit system that eliminates sagging or slumping over time. This characteristic is particularly valuable in reducing thermal bridging, a common issue with other types of insulation that can lead to energy loss and reduced performance. Additionally, the product’s high thermal inertia helps regulate indoor temperatures, providing a phase-shift resistance that mitigates overheating in summer and cold penetration in winter.

For architects, this means designing buildings with long-lasting thermal efficiency that can withstand fluctuating temperatures without sacrificing comfort. The product’s R-value of 3.7 per inch matches that of conventional insulation materials, making it an excellent alternative in both residential and commercial applications. Furthermore, its acoustic properties make it ideal for reducing sound transmission between rooms, addressing one of the core challenges in multi-unit residential projects or mixed-use buildings.

The material’s moisture resistance also plays a crucial role in maintaining indoor air quality by preventing mold growth, a common issue with other natural insulation products. As a result, HempWool aligns with biophilic design principles, supporting healthier living environments. Available in various thicknesses—2″, 3.5″, 5.5″, and 7.5″—and widths that fit standard framing sizes (24″ and 16″ OC), HempWool offers flexibility for architects looking to integrate sustainable practices into diverse project types.

PlantPanel X: Rigid, Renewable, and Resilient Exterior Insulation

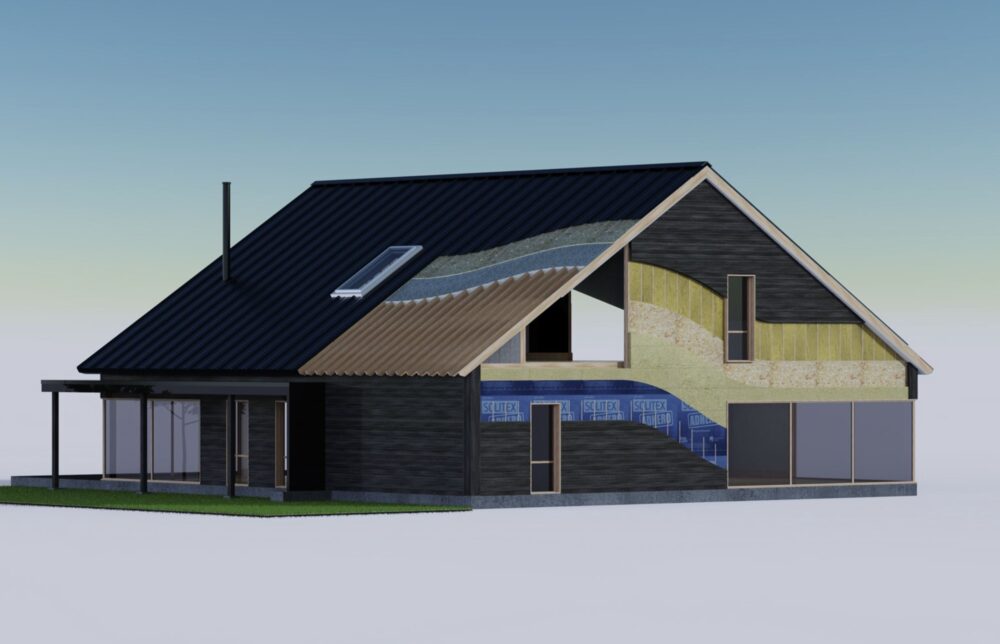

For projects that require continuous exterior insulation, Hempitecture has developed PlantPanel X, a rigid insulation board made from 100% biobased and recycled content. This product is designed for above-grade applications, providing consistent thermal and acoustic performance while being environmentally responsible. Unlike synthetic rigid boards that often contain petroleum-based components and VOCs, PlantPanel X is a VOC-free, non-toxic alternative that architects can confidently specify for green building projects.

One of PlantPanel X’s key features is its dimensional stability, which is critical for maintaining a consistent thermal barrier over time. The board’s R-value of 3.25 per inch ensures effective insulation in diverse climates, while its moisture permeability prevents condensation within wall assemblies. The material’s fire resistance, certified to ASTM standards, adds an extra layer of safety in both residential and commercial applications.

In terms of installation, PlantPanel X is engineered to be lightweight and easy to handle, reducing labor costs and installation time. This quality makes it ideal for projects that emphasize efficient construction timelines without sacrificing sustainability. It is particularly well-suited for split-insulation wall assemblies with rain-screen cladding or roofing materials, providing a durable and adaptable solution for modern building envelopes.

By incorporating PlantPanel X, architects can address one of the most pressing challenges in high-performance building design: creating airtight, thermally efficient exterior walls while minimizing the environmental impact. This approach aligns with standards like LEED and Passive House, where continuous insulation is essential to achieving energy efficiency and occupant comfort.

Hempcrete: Carbon-Absorbing Biocomposite for Sustainable Structures

Another revolutionary product in Hempitecture’s lineup is Hempcrete, a bio-composite made from hemp core and a lime-based binder. Unlike traditional concrete, which is carbon-intensive to produce, Hempcrete absorbs CO₂ during the growth of hemp and the curing process, making it a carbon-negative building material. For architects focused on reducing the carbon footprint of their projects, this material offers an innovative solution that combines functionality with environmental stewardship.

Hempcrete’s thermal mass and moisture-regulating properties make it ideal for creating stable indoor climates. It acts as both insulation and a humidity buffer, absorbing and releasing moisture without losing its thermal performance. This feature is particularly beneficial in climates with significant temperature swings or high humidity levels. Additionally, Hempcrete’s fire resistance (ASTM E84 certified) and sound attenuation properties make it versatile for applications ranging from single-family homes to commercial buildings.

While not a structural material, Hempcrete excels as infill insulation within timber or steel framing. Its lightweight nature reduces the overall structural load while still providing robust insulation. In addition, Hempitecture offers HempBinder, a specially formulated mineral binder designed to enhance the performance and durability of Hempcrete, supporting long-term building integrity.

The flexibility in installation methods—either cast in place or using prefabricated blocks—gives architects creative freedom in incorporating the material into diverse project types. By integrating Hempcrete, designers can create structures that not only reduce carbon emissions but also improve indoor environmental quality.

Leading the Way: Hempitecture’s Recent Projects and Expansion

Hempitecture’s commitment to growth and innovation is evident in its latest ventures. The company recently completed a 33,000-square-foot manufacturing facility in Jerome, Idaho, marking a milestone as the first energy-efficient, nonwoven facility in the U.S. dedicated to bio-based products. This expansion significantly enhances production capacity, supporting the growing demand for sustainable construction materials.

In addition, Hempitecture has secured an $8.42 million grant from the U.S. Department of Energy to establish a hemp fiber processing facility in northeast Tennessee. This project aims to revitalize former coal communities by creating 25 full-time jobs while producing high-performance, carbon-reducing insulation products. Hempitecture is also expanding to New York State, where a new facility will develop novel biobased insulation products supported by a $1.1 million contract from the New York State Energy & Research Development Authority. Hemp-based materials such as these address environmental concerns and meet the practical needs of architects and builders looking to create resilient, healthy, and energy-efficient buildings. More design professionals are embracing the potential of hemp for a greener, more sustainable future.