When it comes to flying, comfort and individual space shape the travel experience. PriestmanGoode designs cabin interiors for airlines like the customizable Airspace cabin for Airbus launched at Aircraft Interiors Expo in 2016. They also provide award-winning branding for individual airlines including Qatar Airways, Swiss Airlines, TAM Airlines Lufthansa and more.

In April 2016 Paul Priestman was interviewed live on BBC World News about the evolution of aircraft interior design over the last two decades. You can watch the interview here. ArchiExpo e-Magazine spoke with Luke Hawes, designer and co-director at PriestmanGoode, to learn how the company uses cabin design to improve flight experience.

ArchiExpo e-Magazine: What tools do you use to design aircraft cabins?

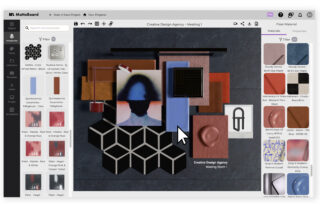

Luke Hawes: We use many types of high-end 3-D CAD and visualization software depending on the project, whether supplying technical data to seat vendors or files for movies. The software allows us to build a skeleton model to visualize materials and colors in photo-realistic impressions of the cabin. We can also render through sequences, creating airline-marketing movies.

Check out the latest from a number of 3-D CAD software programs here.

ArchiExpo e-Magazine: What materials do you use?

Luke Hawes: Making materials fly is the biggest challenge. There’s a whole floor in our London studio dedicated to material innovation. We also work with major international suppliers, especially trim and finish suppliers like Botany, Rohi, Lantal, Anker, Schneller and Isovolta, to look for new ways of making authentic-looking lighter weight materials. For example, granite tray tables with 10 millimeters of material thickness, like those on United Airlines domestic fleet which debuted Fall 2015, only 2-3 millimeters of granite give the visual effect. The rest is a substrate of another much lighter weight material.

ArchiExpo e-Magazine: How do you go about reducing weight and increasing space onboard?

Luke Hawes: While a correlation between weight and space exists, it doesn’t guarantee one to the other. We need weight reduction out of everything we do, from seat structure and materials, down to accessories like pillows and blankets, as an economical approach for airlines to reduce fuel costs.

Creating space and the illusion of space is for passengers. We create a feeling of space through layout and intelligent use of lighting. We make elements look like they’re floating by washing light behind them or setting furniture off the floor and lighting the floor. When working with Airbus and Boeing, they have their own lighting suppliers but for customized lighting features Schott is our preferred partner.

We also work to gain half-inches all around, adding to seat width, shoulder width and knee space, particularly in economy class. We use spatial and architectural design tricks in order to meet airline economy class requirements of 32-34 inch seat pitch. We reset literature pockets and move functional items of seat backrests to increase living space. Passengers feel a difference with just millimeters more.

ArchiExpo e-Magazine: How does designing for an aircraft manufacturer differ from an airline?

Luke Hawes: With aircraft manufacturers, like Airbus, we’re creating cabin interiors to sell to airlines. We must have layout flexibility so airlines can apply their brand, open comfortable spaces, and have impressive-looking architecture and lighting systems to seduce airlines to want that particular aircraft type.

We then pick up from the other side, helping airlines customize the interior to reflect their brand. Sometimes that’s the country’s culture, local art and architecture, signature crafts like weaves or mosaic tiles. Designing a cabin interior normally starts with a week or two visiting the country or the area, looking at sites of natural heritage, natural landscape and local craft or architecture to form a brand story. We apply these to all components of the aircraft through pattern, color and surface finish. Rich cultural histories of airlines like TAM, Thai or Turkish make the task easy.

ArchiExpo e-Magazine: How does each flight class influence design differently?

Luke Hawes: Business class passengers expect more in terms of comfort than economy class. There need to be separate modes for relaxing, sleeping and watching entertainment. Seats must convert to fully flatbeds. Business-class is the big competitive market where airlines predominantly make their money, so they always need to be innovating the configuration for maximum seat number, while providing lifestyle functions. First-class has more space to customize.

ArchiExpo e-Magazine: How do you streamline airplane galleys?

Luke Hawes: We dress the galley so it doesn’t look like you’re boarding through the kitchen. We create a welcoming area with customized sidewalls facing the entrance in order to hide what would be visible kitchen appliances. We also use blinds, door systems, lighting and branding so passengers feel like they’re entering through a reception area.

ArchiExpo e-Magazine: What lasting innovations have you made in cabin design?

Luke Hawes: When we first started in the industry, the airline design approach was like trying to fit boxes into a tube. They don’t fit particularly well, which leads to wasted space. We treat the cabin as one product to make the architecture fluid and get a better fit, integrating functions as much as possible. Rather than going to manufacturers of each different product and trying to fit them together, we find one supplier who can do the whole cabin or several suppliers who will work together to create a seamless look. We’ve established relationships with several suppliers to accomplish this goal. For seats and monuments, we have a particular affiliation with BE Aerospace but also work with Recaro, Thompson Aero Seating, Stelia Aerospace, Zodiac, Jamco, Aim Altitude and Bucher. Our manufacturers for In-Flight Entertainment systems are Zodiac, Panasonic, Rockwell Collins and Thales, and trim and finish suppliers mentioned earlier.

Also, when we apply the airline’s brand, it’s seamless and goes through the whole aircraft—like a wallpaper pattern, for example. We also make sure there’s power throughout so everything can be illuminated.