With the construction sector under growing pressure to decarbonize building stock, sustainable renovation has emerged as a critical solution. By improving energy efficiency, minimizing waste, and reducing whole-lifecycle carbon, renovations are paving the way for a greener future. Discover how cutting-edge steel innovations are transforming the possibilities for sustainable building practices.

This sponsored article was written by ArcelorMittal Construction.

Steel in Modern Construction and Renovation

Accounting for about 37% of global CO2 emissions, the construction sector bears a unique responsibility to tackle climate change head-on. To do that successfully, we must address the global warming potential of buildings across their entire lifecycles.

The EU’s recently introduced legislative framework, the Energy Performance Building Directive (EPBD), makes this ‘whole-lifecycle mindset’ mandatory on many projects. Aiming for a fully decarbonized building stock by 2050, one of the key strategic elements of the EPBD is to drive renovation.

From a sustainability perspective, renovations make a great deal of sense. Refurbishments can significantly improve the energy performance of existing building stock. Plus, compared to full demolitions and rebuilds, renovations prevent waste and limit embodied carbon within the built environment.

Steel: Infinitely Recyclable, Durable, and Lightweight

Steel offers many benefits that make it an ideal material for sustainable renovations. It is infinitely recyclable, durable, and low maintenance. It provides an excellent strength-to-weight ratio, is versatile in design and suitable for composite configuration.

Steel’s only drawback relates to its environmental impact when extracted and processed as a virgin material. However, innovation in recycling, electric arc furnaces, and renewable energy generation can circumvent these disadvantages. ArcelorMittal Construction products manufactured with XCarb® recycled and renewably produced steel can reduce embodied carbon in products by as much as 67%.

Ventilated Façade Systems: Cost-efficient, High-performing, and sustainable

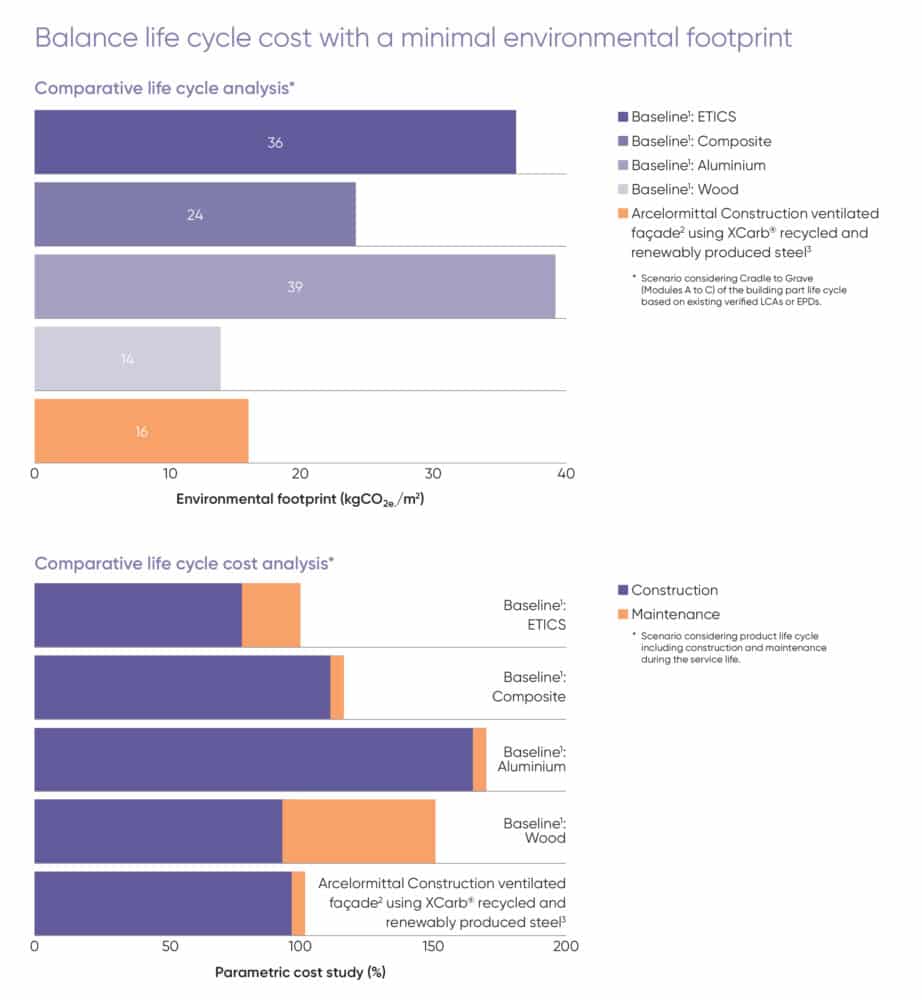

As demonstrated in the graphs below, ArcelorMittal Construction’s ventilated façade systems made from XCarb® recycled and renewably produced steel deliver excellent sustainable performance across their lifecycles.

Ventilated façade systems are a popular choice in renovation projects due to their excellent fire safety and thermal performance, as well as the range of aesthetic options they provide. Furthermore, the energy efficiency and appearance of any building can be quickly transformed through ventilated façades with minimal disruption to occupants during the renovation process.

Renovation projects require materials and systems that strike the perfect balance between cost, performance, and environmental impact. Ventilated façade systems excel in this regard, thanks largely to their ‘highly industrialized’ nature.

Throughout design, manufacturing, assembly, maintenance, and operation, highly industrialized systems benefit from elevated quality control, standardization, and advanced engineering. They are efficient, reliable, and user-friendly.

D2B® System: Accelerating Renovation Through Prefabrication

Another industrialized ArcelorMittal Construction solution is the D2B® curtain wall system. This modular range is designed to optimize time, cost, and safety on site, as well as energy efficiency in operation.

Like all good prefabricated solutions, D2B® pushes the advantages of highly industrialized systems to the extreme. Assembled on the factory floor instead of on-site, it offers consistent quality and rapid installation.

Data shows that D2B® can be installed up to 40% faster than traditional systems, with a three-person team able to install 200m² per day. This speed, alongside impressive low weight and insulating properties, makes D2B® a highly convenient, cost-effective, and sustainable choice for renovation projects.

Innovation Beyond Renovation

Steel systems don’t just excel in renovation projects; they are also equally well suited to brand-new sustainable developments. When combined with high-quality insulation – for example, in composite sandwich panels – steel products result in buildings with exemplary energy efficiency.

ArcelorMittal Construction has worked in close partnership with Moasteel House to create one such low-carbon system. Utilizing ArcelorMittal Construction’s plug-in solar roofing solution, Helioroof®, Moasteel House can provide dwellings that generate more energy than they use in operation. This performance has been recognized by the Solar Impulse Foundation, a respected non-profit organization that certifies products that address environmental challenges while also enabling economic growth.

In addition to its remarkable sustainability credentials, the Moasteel House residential solution is lightweight enough to be used on almost any type of terrain or subgrade. It is suitable for use in areas at risk of seismic activity, and, after completion of works on the foundations, can be assembled in under a week.

Steel is a cornerstone of sustainable renovation and construction, offering unparalleled recyclability, durability, and adaptability. Paired with innovative modern construction techniques, such as ventilated façades and prefabrication, it provides a pathway to achieving energy-efficient, environmentally sound buildings that meet modern regulatory demands.

In the race to decarbonize the built environment, steel’s role is clear. It’s strong, elegant, and sustainable: the ideal material for building a brighter future.

Find out more ways ArcelorMittal Construction can support sustainable construction and renovation. Learn more here.