On November 24, we visited the ongoing construction of Campus OMNES in Marseille. Scheduled to be delivered in September 2026, we delight in the short-circuit architecture mixed with local style and skills.

In a hurry? Here are the key points to know:

- A low-carbon, short-circuit build: The campus uses regionally sourced materials like compressed earth infill and mobilizes local artisans and short supply chains to reduce environmental impact.

- Hybrid prefab structure: A prefabricated concrete frame paired with non-load-bearing earth panels ensures durability, thermal comfort, and long-term adaptability of the façade and interior layouts.

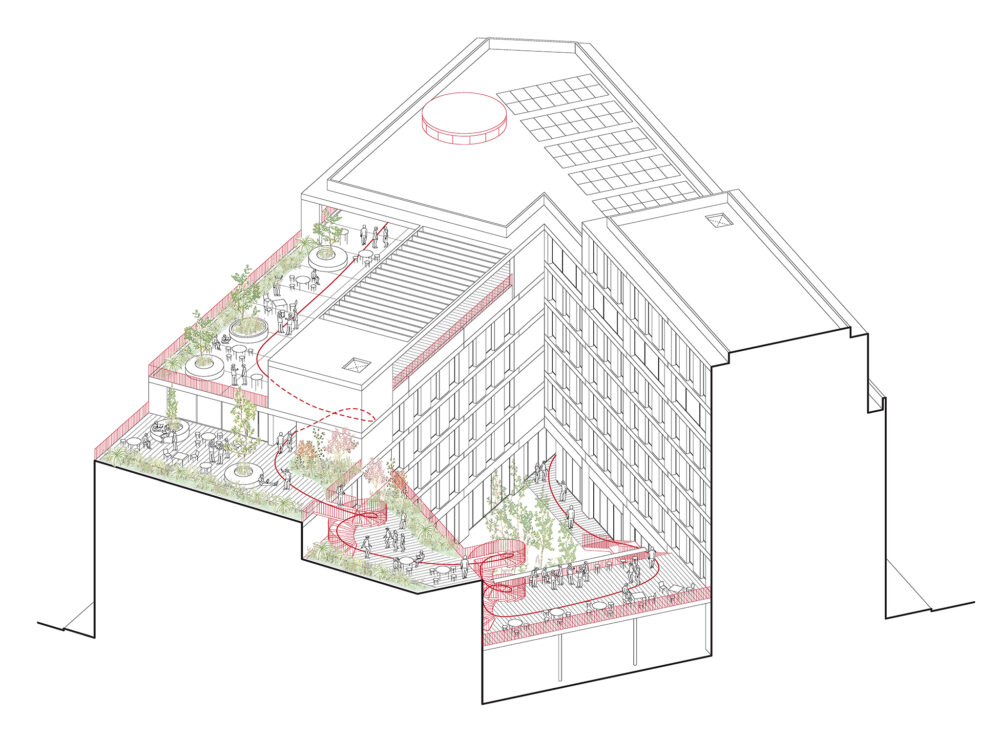

- A porous, civic-minded design: A vertical public space and large street-facing windows create visual and spatial connections between students and the neighborhood, turning the campus into an open, shared urban landmark.

Scheduled to be delivered in July 2026, the OMNES Campus is already establishing itself as an architectural landmark of ecological transition within Marseille’s Euromed 2 development. It’s a low-carbon “village campus” that brings together seven higher-education institutions with a strong commitment to sustainable urban development. Designed by Céline Teddé and Jérôme Apack at AT studio for OMNES Éducation and developer Redman, the project occupies a strategic corner of Place Marceau, at the heart of a district undergoing significant transformation. More than a new educational facility, the campus positions itself asa demonstrator of what local, resource-efficient, collectively engineered architecture can look like today.

The design team prioritized “local”, be it in sourcing, material intelligence, and local craft. The building combines locally produced components, regional earth resources, Marseille-inspired construction traditions, and a network of skilled manual labor. Inside, a vertical public space that links stacked communal areas and terraces, encouraging informal encounters between the seven schools housed within. In keeping with the client’s request for openness and green space, one of the main façades operates almost like an urban storefront, giving passersby a direct view into the library, the student hall, and the central courtyard, turning the campus into a porous civic interface rather than a closed academic block.

WATCH our video tour of the campus under construction here.

Prefabrication, Structural Logic, and a Modular Future

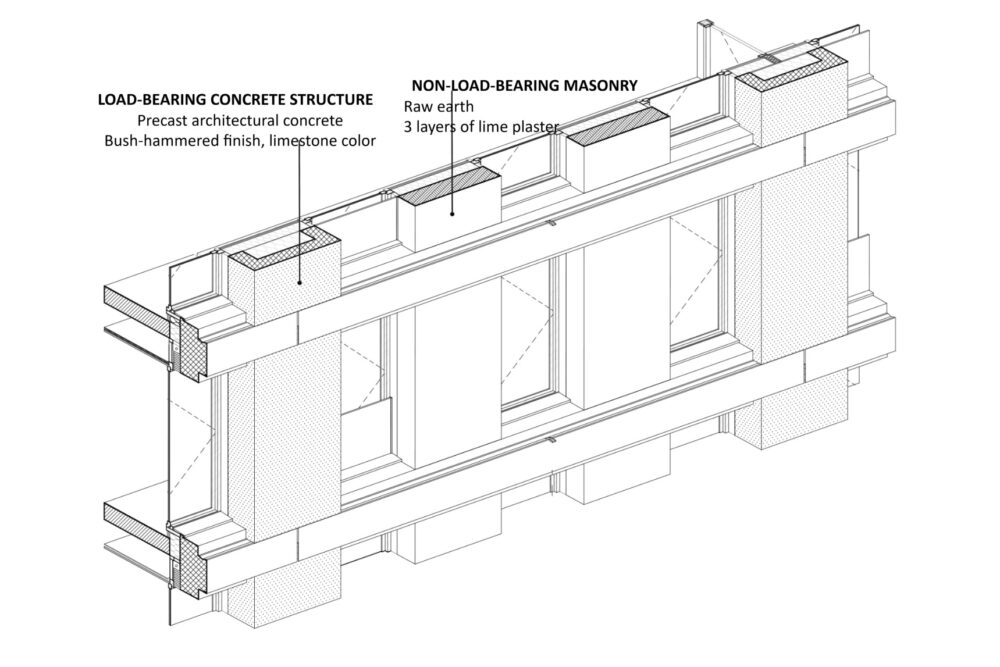

The architectural identity of the campus is shaped by the interplay between its structural elements: vertical load-bearing concrete piers and horizontal concrete beams, both prefabricated. The vertical piers feature a textured, grainy finish, while the horizontal elements are smooth, forming the expressive structural grid. In the infill bays between these vertical piers, the architects introduced columns of compressed earth blocks. This alternation between bush-hammered concrete structure and lime-coated raw earth infill allowed the building to meet the stringent requirements of the Architectes des Bâtiments de France (ABF), who oversee heritage-sensitive sites.

“When we were designing it, we thought it might be smarter to use non-load-bearing earth, which was more of a filler, to make the project safer. We know that there are still a lot of disruptive elements that can happen. So we have a load-bearing frame, which is what we call a filigree, meaning it’s a blade-cut concrete slab, which guarantees the durability of the building,” Jérôme Apack said during the visit.

The use of concrete is intentionally moderated rather than rejected. As the architects emphasized during the site visit, the goal is not a dogmatic elimination of carbon-heavy materials but an intelligent, balanced approach combining durability, low carbon, and structural reliability. Earth infill contributes significant thermal inertia, helping stabilize indoor temperatures throughout Marseille’s hot seasons, while the concrete frame ensures long-term robustness.

“GT Construction, responsible for posing the blocks, have completed three levels as of now. This represents more than a thousand blocks,” Apack said.

This structural clarity also opens possibilities for future adaptation. The building has been planned and dimensioned in modular lots so that, decades from now, it could be reprogrammed into offices, housing, or other uses without requiring extensive structural transformation.

“Filling with earth also allows the façade to evolve. Later down the road, if the building needs to be renovated or repurposed, the façade can also be modified and, depending on what we want to do inside, new partitions can be added,” Céline Teddé said during the visit.

The facade system—composed of independent structural piers and non-load-bearing earth-filled panels—could be modified or replaced while retaining the stability of the original frame. In an era of rapidly shifting urban and educational needs, this adaptability is a key part of the campus’s ecological intelligence.

Short-Circuit Construction: A Precise, Sometimes Imperfect, Local Process

While the intention was to reuse soil directly from the Marseille site, contamination ruled it out. A second candidate—the soil from another Redman development—proved unsuitable after testing. Ultimately, the team selected material from the Vallon-Régny construction site, a choice supported by extensive geotechnical analysis and compatibility tests for compressed earth brick production.

The initial plan was to process the soil on a mobile production unit installed near Vallon-Régny, ensuring minimal transport. However, a technical setback emerged: the brick-compressing machinery, operated by Nice-based Filiater, proved electronically sensitive to vibration and movement. As a result, the soil had to be transported to the company’s facility in Nice, where the bricks were produced before being delivered back to Marseille. Though counterintuitive to the short-circuit philosophy, the full carbon assessment showed that this detour had only a negligible impact on the project’s environmental footprint. It’s an instructive reminder that local construction is not always linear but can remain low-carbon when well-orchestrated.

“We visited two companies specialized in working with soil, particularly in prefabrication. There is one near Lyon that produces prefabricated rammed earth blocks, but they were not yet fully developed, particularly in terms of production speed. In other words, they were not able to deliver as many blocks as we wanted,” Apack said.

Beyond carbon calculations, the team also had to ensure the mechanical performance of the earth blocks. Since the infill panels support large wooden window frames, their compressive strength and interaction with the horizontal beams were carefully assessed. Additional brackets were engineered to distribute loads and prevent the lime-coated earth from crumbling under the weight.

These structural calibrations underline the precision required when integrating geosourced materials into a contemporary construction system.

“On top of the brick, we’ll apply a lime plaster. It’s a heritage plaster that has been tested so that we don’t get a ghosting effect with the joints. It will be 2 or 3 cm thick and will allow the earth to breathe,” Apack said.

Faced with a tight construction schedule, with delivery scheduled for September 2026, the project management team made the strategic decision not to use earth as a load-bearing element, but only as fill, inserted into a concrete post-and-beam system. This choice ensured the technical and insurance feasibility of the project while preserving the earth material. The AT agency thus drew on vernacular construction methods, taking inspiration from traditional Marseille buildings: masonry infill, stone chaining, and vertical piers. This style has been reworked here with bush-hammered concrete chains and trumeaux between windows housing prefabricated blocks of compressed raw earth, coated with lime.

A Prototype for Future Metropolitan Construction

Campus OMNES stands as more than a new educational facility; it is a prototype for what metropolitan construction could become. The project demonstrates how short-circuit production, low-carbon materials, and vernacular-inspired techniques can coexist with prefabrication, regulatory constraints, and the requirements of contemporary educational programs.

Rather than idealizing a return to pre-industrial methods, the architects advocate a pragmatic, resilient, contextually informed construction logic—one that reduces carbon, empowers local actors, and plans for long-term adaptability. Earth, in this scenario, becomes neither symbol nor nostalgia, but an operational material that engages directly with the ecological and cultural challenges of today’s built environment.

Through its reliance on local knowledge, its hybrid structural vocabulary, and its emphasis on communal spaces, the OMNES Campus positions itself not only as a model within Euromed 2 but also as a wider exploration of how architecture can genuinely integrate sustainable practices at every level—from material sourcing to urban experience.

TECHNICAL DETAILS

- Surfaces: 6,200 m² of floor space, landscaped area in the center of the block

- Specific features: Prefabricated filigree load-bearing structure made of concrete posts/beams; Filling with compacted excavated raw earth; Seawater loop

- Label: BDM Silver Level

- Dates: 2023 – 2026; Assembling the building began in September-October 2025; Completion scheduled for July 2026