By Alexander Zilberman AIA, NCARB, Founding Principal and Architect, Alexander Zilberman Architecture, New York City

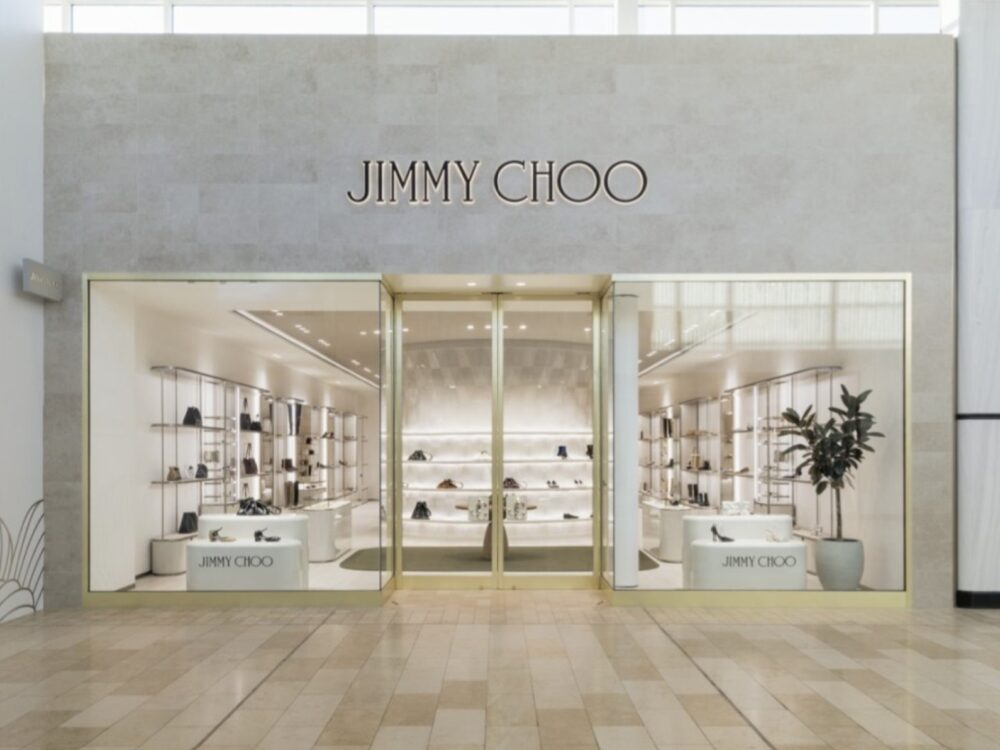

Success in built environments for luxury clientele centers on the predictability of outcomes. Architects creating brick-and-mortar retail venues for major global brands learn this lesson early on, and many years spent specializing will reinforce the prevailing value proposition in this highly competitive sector: With store date openings announced long in advance, brands are willing to accept high costs and long lead-times as long as outcomes of budget, quality, and schedule can be depended upon. As a result, designers increasingly rely on precision-engineered, shop-fabricated components to produce immersive retail experiences with bespoke aesthetics.

While some may still associate prefabricated materials and systems with lower-cost projects and delivery, there is no better way for us to maintain control over the challenges or “pain-points” that impact results, such as:

- The on-site construction timetable

- Reliance on local trades

- Durability, i.e. reliable life span of the built environment.

By and large, the more components that are produced in a controlled environment and the more the project becomes an installation rather than an on-site build-out, the better the quality of the joinery and consistency in materials – and these are the elements of the in-person retail experience that most luxury goods brands value highly.

The ‘Hybrid Prefab’ Approach

The most effective way to control for the pain points is to design as much as possible for construction with prefabricated systems that are ready to assemble on site, with as few specialized trades as possible. To produce high-quality, unique, and bespoke immersive spaces that translate the brand into a memorable experience, most projects require some traditional construction, and many benefit from hand-crafted work by skilled artisans. This hybrid prefab method strikes a balance between predictable results and vibrant design.

A great example of hybrid prefab construction for retail can be seen in Precision Watches, a freestanding flagship and headquarters in the Philadelphia, PA, suburb of Lower Gwynedd for a family-owned retailer specializing in luxury timepieces. Precision offers individually branded boutiques on the ground floor where guests peruse offerings by Cartier, Rolex, Omega, and Tudor. A watch movement-inspired grand stair connects to a second floor, with lounge seating and more options for lovers of fine watches to explore.

Our design called for prefabricated systems for the structural frame of the 9,000-square-foot building as well as for many interior elements – each of the four mini-boutiques on the main floor, for example, had to comport according to the demands of a major celebrated brand, so installing precision-engineered, ready-to-assemble components eliminated any uncertainty. Meanwhile, many traditional construction methods were employed, and skilled artisans were engaged to produce a distinctive façade of custom Roman brick over a split-face limestone base – an homage to the vernacular of the locally familiar Quaker architecture.

Precision Watches was delivered within the promised construction timetable and budget, and both the owner and the brand teams have remarked that the results exceeded expectations.

Prefab for Luxury Homes: Prefab Flatpack Components Solve Most Challenges

Opportunities for the hybrid prefab approach to design and construction extend well beyond retail. Exploring opportunities in residential and hospitality, we find that the method provides a path to successful high-end development with a focus on wellbeing and connection to nature.

While our firm began several years ago to develop a proprietary hybrid prefab system for luxury ADUs, we recognized that utilizing shop-fabricated systems becomes especially valuable in remote locations. Luxury and exclusivity often go hand-in-hand with hard-to-reach destinations – desert, mountain, beach – but these locations each come with design challenges such as abbreviated construction seasons and scarcity of available skilled trades.

Developers in these regions benefit from an approach that controls those same pain points. In a ski resort area like Park City, Utah, there is a growing demand for luxury single-family development, but the remote location makes it hard to secure skilled teams, and the “mud season” in Spring reduces the available construction calendar by several months. Other challenges include the availability of materials, municipal infrastructure, and access for large vehicles, heavy equipment, and crews.

By executing the project as an installation of pre-manufactured flatpack components, we solve for most of the uncertainty stemming from these pain points. Better still, in some cases, we can lift fully-assembled modules into place using small cranes, to be secured to the foundation by just a small crew.

Delivering Peace of Mind via the Construction Process

Our firm’s hybrid-prefab concept focuses on principles of human-centered spaces from the inside out. We design panels and component types with fixed dimensions that relate to the proportions of the human body, and maximize their use.

This approach minimizes the occurrence of variable components, and helps solve for anything that may need on-site fitting. Eliminating much of the uncertainty allows us to focus on producing a high-quality living environment with bespoke aesthetics that connects residents to the pristine natural beauty of the surroundings. At the same time, the construction process delivers peace of mind to the developers regarding time, cost, and quality, so they can focus on selling the home as a turnkey delivery to the new homeowner.

One luxury residence we have designed for a development near Park City utilizes a variety of high-performance, technologically advanced, renewable, and sustainable materials, including mass timber, structural insulated panels, and metal roof insulated panels. These are made to fit together and unitized for flat-pack transport, a method that can be replicated for economies of scale. These systems provide better structural stability than stick-built and, when assembled, create an airtight, energy-efficient envelope. They also help realize a design that connects occupants to nature through biophilic material choices and panoramic exterior views, fostering health and wellbeing.

One additional note: If a certain style is preferred or mandated by the jurisdiction or by the development community guidelines, the exterior cladding and other visible elements can be sourced locally and applied by area artisans. But whatever the mix of methods used in the hybrid approach, it is the shop-fabricated, assembled-on-site elements that will control for those pain points while delivering an elegant, one-of-a-kind home that connects users to nature.

About the Author:

Alexander Zilberman, AIA, is the founder and principal architect of Alexander Zilberman Architecture PC (AZA), a globally active studio working on luxury projects in residential, retail, hospitality, and workplace, among others. As an architect, artist, and designer, he translates brand identity and experience into architectural solutions that reflect a focus on craft, authentic materials, and detail. Zilberman’s work with well-known brands such as Versace, Michael Kors, and Aston Martin can be seen from New York to Miami, Beverly Hills, and Dubai.