In this opinion piece, Simplus Systems CEO Tim Sweeney and CIO Timothy Lorang discuss the idea of rethinking prefab construction and provide insights into panelized systems.

Prefabricated buildings have long been saddled with misconceptions. The word still evokes images of cheap, temporary structures—cookie-cutter boxes lacking architectural integrity or long-term durability. Many design professionals continue to associate prefab with limited aesthetic control, poor performance, or rigid systems that force creativity to conform to factory constraints.

But the prefab industry has evolved—quietly, dramatically, and in ways that many in the profession haven’t fully seen. Today’s high-performance panelized systems bear little resemblance to the prefab of the past. They are not only faster and more efficient to assemble, but also capable of meeting the most rigorous energy and resilience standards.

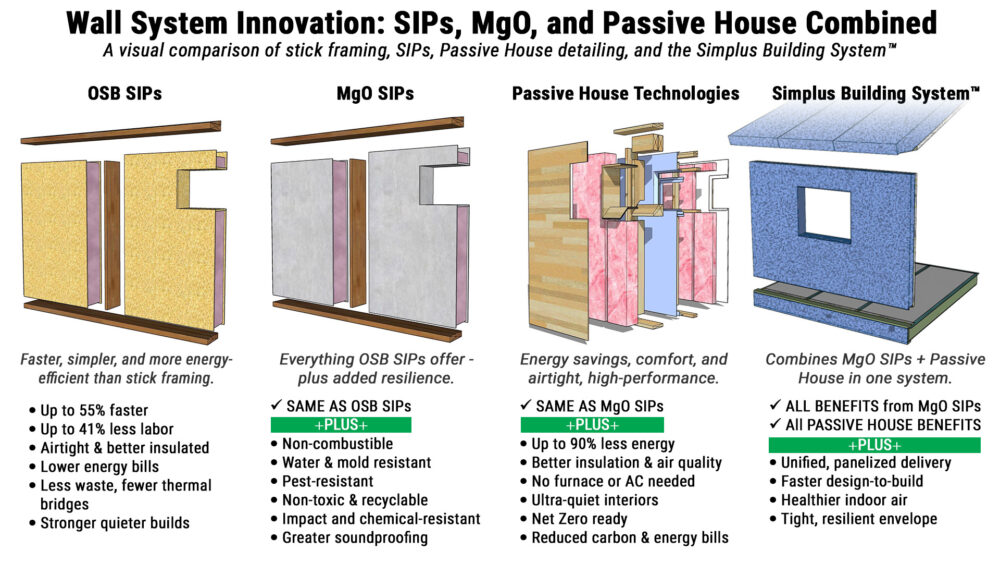

Simplus Systems is part of this new generation. Its building system combines factory-fabricated magnesium oxide (MgO) panels with Passive House design principles to deliver smarter, faster, and more resilient construction. The result is a new standard for panelized building—one that accelerates construction timelines while offering superior performance in fire resistance, energy use, and occupant health.

In a time of climate urgency, labor shortages, and growing demand for durable, healthy buildings, it’s worth taking a second look at what prefab can truly offer—when it’s done right.

Panelized Systems That Save Time—And Deliver More

One of the most enduring promises of prefabrication is speed—and in panelized construction, that promise is now a proven advantage. In a widely cited 2006 Time & Motion study by RSMeans, SIP (structural insulated panel) construction was shown to reduce installation time by 55% and labor costs by 41% compared to conventional wood framing with sheathing and batt insulation. Using a simple 2-story design as a test case, its findings have remained relevant across geographies and project types.

More recent studies—including McKinsey & Company’s 2019 global report and a 2023 review by the Modular Building Institute—confirm that panelized and other off-site systems regularly shorten build timelines by 20–50%. These gains are especially valuable in tight labor markets or in areas with short building seasons or permitting pressures.

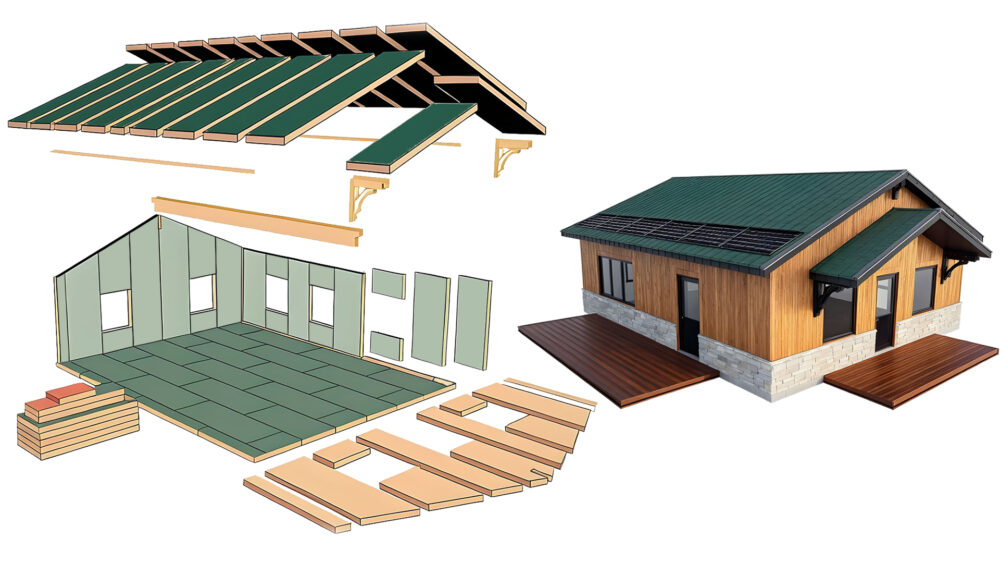

Importantly, Simplus Systems’ panelized approach is not just “modular” in the volumetric sense. While Simplus does capitalize on using prefabricated plumbing walls where feasible, its approach is not constrained to using factory-finished boxes or other rigid shapes. Instead, the Simplus Building System arrives in pre-fabricated panels that are precision-cut to the architect’s specs, ready for rapid installation on site. The entire building can be configured as desired with ready-to-assemble wall, floor, roof, and deck panels that can be finished per the client’s wishes. There’s no need to bring in separate trades for framing, sheathing, and insulating—Simplus panels combine all of these layers into a single, efficient system, and the panel installers are usually the same carpenters doing the other work too.

Resilience, Built In

Speed alone isn’t enough. In a world of wildfires, floods, and rising climate risks, resilience must be built into the structure itself. And this is where panelized construction—especially with materials like magnesium oxide—offers a critical advantage.

MgO is inherently noncombustible. Unlike wood-based systems, it doesn’t fuel fire, emit toxic smoke, or degrade in extreme heat. Simplus panels have been successfully applied in wildfire-recovery and urban infill projects for this reason. They are also mold-resistant, pest-resistant, and highly water-tolerant, giving them an edge in high-humidity or disaster-prone environments.

Beyond durability, resilience means indoor safety. A tightly sealed panelized envelope minimizes smoke intrusion, allergens, and noise—all while improving thermal performance and reducing energy bills. These benefits matter even more in low-income or health-sensitive building types like affordable housing, clinics, or schools.

In short, panelized MgO systems deliver more than faster construction—they result in buildings that last longer, perform better, and protect the people inside.

Design Without Compromise

If prefab once implied rigid, uninspired architecture, panelized systems like Simplus flip that notion entirely. Design flexibility is a core strength of panelized construction.

Unlike volumetric modules, Simplus panels are designed around the architect’s vision—not the other way around. Openings, cantilevers, and irregular geometries can be accommodated in the digital fabrication process. Exterior finishes and claddings are fully customizable. This allows panelization to support a full range of building types and aesthetics—from minimal modernism to vernacular regional styles.

At the same time, high-performance metrics come built in. With Passive House detailing, continuous insulation, and factory-installed air sealing, buildings can achieve top-tier energy performance without needing additional trade coordination. For designers working toward net-zero or carbon-smart goals, panelized systems can dramatically reduce time, complexity, callbacks, and cost.

Panelization also means fewer surprises on site. Because fabrication and installation are tightly aligned, what’s drawn is what gets built—without the delays or rework common in conventional construction.

Why the Future Is Panelized

The pressures facing the building industry aren’t new—but they’re intensifying. We’re seeing a global shortage of skilled labor, escalating material costs, rising energy standards, and more frequent natural disasters. Architects and developers need smarter systems that solve multiple challenges at once.

Panelized construction—especially when paired with Passive House strategies and resilient materials like MgO—is uniquely positioned to meet this moment. It shortens project timelines, improves build quality, and supports climate-adaptive, healthy housing.

Tim Sweeney, CEO of Simplus Systems and a Certified Passive House Designer, puts it this way:

“We’re not just building faster. We’re building stronger, healthier, and more energy-efficient spaces—without compromising design.”

Through his work with the U.S. Department of Energy and the Lawrence Berkeley National Laboratory’s IMPEL program and projects across California and Nevada, Sweeney is helping developers, policymakers, and designers reimagine what high-performance construction can look like—on deadline and on budget.

As the building industry evolves, panelized systems offer a compelling answer to the question: how do we build smarter?