By embedding high-performance steel fibers into the mix, engineers can strengthen concrete, speed up construction, and reduce embodied carbon at once.

In a hurry? Here are the key insights:

- Steel-fiber reinforcement distributes tensile capacity throughout the concrete, improving ductility and crack control compared to traditional rebar.

- SFRC reduces on-site labor by eliminating cutting, bending, and fixing of steel bars, enabling faster and cleaner construction.

- The material’s post-crack performance improves from strain-softening toward strain-hardening when fibers are combined with optimized rebar layouts.

- Flexural residual strength, measured through the BS EN 14651 test, remains the industry benchmark for evaluating fiber effectiveness and durability.

- Hybrid systems using steel fibers have demonstrated up to 50% reinforcement reduction and significant CO₂ savings in large-scale foundation projects.

As global construction intensifies, concrete’s environmental and structural drawbacks are becoming impossible to ignore. It accounts for nearly 40% of all materials used worldwide, and its cement component alone generates around 8% of global CO₂ emissions. As urban programs accelerate and performance expectations rise, architects, engineers, and developers are increasingly compelled to rethink how we reinforce concrete—or whether entirely new approaches can deliver the durability and efficiency today’s projects demand.

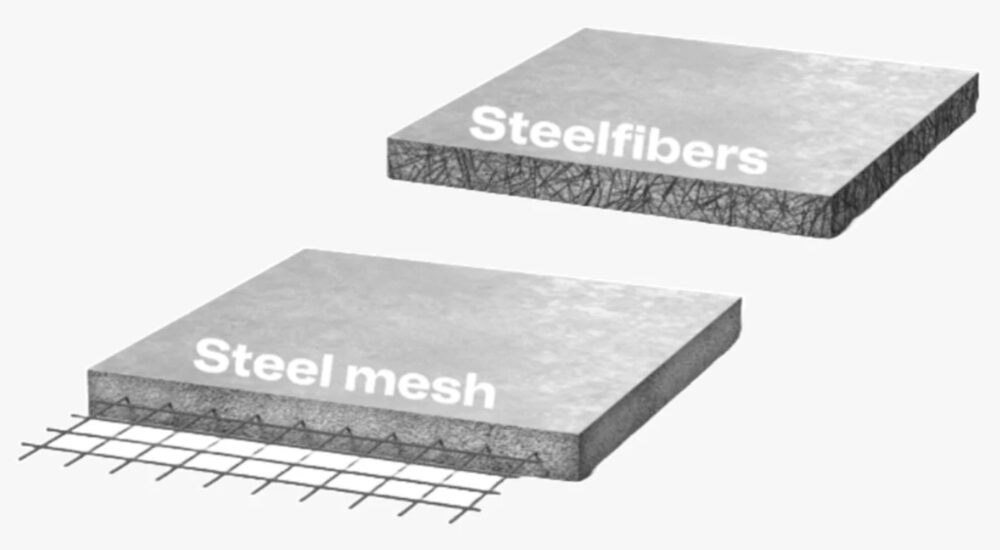

Against this backdrop, steel-fibre-reinforced concrete (SFRC) has emerged as one of the most promising alternatives. Instead of relying solely on discrete steel bars, SFRC incorporates thousands of small fibres throughout the mix, offering distributed tensile resistance, improved crack control, and enhanced post-crack ductility. Research shows that the right fibre geometry and dosage can markedly improve toughness, flexural strength, and durability, while reducing conventional reinforcement requirements and speeding up construction. SFRC is shifting from a niche material to a strategic solution. It invites the construction sector to reconsider how concrete can perform in a lower-carbon, higher-efficiency future.

How Steel Fibers Enhance Concrete Performance

Concrete’s fundamental limitation lies in its brittleness: once subjected to tensile stress, it cracks suddenly and loses load-carrying capacity with little warning. Steel fibers fundamentally alter this behavior by introducing a distributed, multidirectional reinforcement system within the concrete matrix itself. Speaking at The Big 5, Ahmad Mandalawi, Regional Structural and Specification Engineer at Bekaert, explained:

“The steel fiber acts like a bridge to transfer the stresses… allowing the concrete to gain more energy before full failure.”

This energy absorption is central to the enhanced toughness, ductility, and resilience observed in steel-fiber-reinforced concrete (SFRC).

Research published over the past decade consistently demonstrates quantifiable improvements: depending on fiber geometry, anchorage, and dosage, SFRC can increase flexural strength by 10–40%, splitting tensile strength by 15–45%, and significantly extend post-crack load capacity. These effects derive from the fibers’ ability to arrest microcracks before they become macrocracks, redistribute stresses across a larger internal area, and delay the onset of catastrophic failure. Fiber shape also matters—hooked-end fibers, for example, provide better mechanical anchorage and thus greater post-crack resistance than smooth or straight fibers.

For architects, engineers, and developers, these mechanical enhancements translate directly into better performance on the ground: improved resistance to shrinkage cracking, heavier load capacity in slabs, superior fatigue behavior under repetitive stresses, and reduced maintenance requirements over the structure’s lifespan. Instead of relying solely on rebar to resist tension in one direction, SFRC offers a three-dimensional reinforcement network that engages immediately when cracking initiates. This transforms how the concrete behaves under service conditions and expands its use in demanding applications such as industrial floors, pavements, tunnel linings, and precast elements. Ultimately, the incorporation of steel fibers makes concrete not just stronger, but measurably more predictable and resilient over time.

Efficiency Gains: Reduced Labor, Faster Construction, Cleaner Sites

Beyond improved mechanical performance, one of the most compelling arguments for steel-fiber-reinforced concrete lies in its impact on construction efficiency. Traditional reinforcement workflows—transporting, cutting, bending, tying, and correctly positioning rebar—are among the most labor-intensive stages of concrete construction. They demand skilled labor, contribute to site congestion, and introduce multiple opportunities for delay. By contrast, steel fibers eliminate many of these steps.

When fibers are mixed directly into the concrete, reinforcement becomes an integral part of the material, not a separate installation process.

As Mandalawi noted, the result is faster construction, reduced handling of steel on site, and overall cleaner and more organized workflows. These gains are particularly significant on large-format pours such as industrial slabs or logistics platforms, where mesh placement can bottleneck progress. SFRC also reduces the need for storage areas for rebar or mesh, simplifying logistics on constrained sites often found in dense urban developments. In factory-controlled environments—precast plants, segmental tunnel-lining production, or modular construction—the advantages scale even further. Controlled dosing ensures uniform fiber distribution, mixes can be optimized for performance, and production cycles become more predictable.

From a sustainability standpoint, the reduction in rebar translates to fewer deliveries, less packaging waste, and lower embodied carbon associated with steel processing and transportation. Cleaner sites also offer safety benefits—fewer tripping hazards, fewer sharp materials, and less manual handling of heavy steel elements. Taken together, the shift toward SFRC aligns with wider industry goals: minimize labor bottlenecks, increase automation, reduce material waste, and accelerate project timelines. In an era pushing for more industrialized construction and lower environmental impact, SFRC provides a pathway to build faster and smarter without compromising performance.

Technical Behavior: From Strain-Softening to Strain-Hardening

The technical advantage of steel-fiber-reinforced concrete becomes most apparent when examining its behavior after cracking. Plain concrete exhibits classic strain-softening: once cracks form, load capacity drops sharply, leaving the structure vulnerable to brittle, sudden failure. Adding steel fibers profoundly changes this response. Instead of an abrupt decline, the load-deflection curve stretches, reflecting a material capable of sustaining load even after cracking. This shift in post-crack behavior is central to the toughness improvements frequently cited in laboratory and field studies.

In some high-performance configurations—particularly with optimized fiber volume fractions, well-anchored fiber geometries, and carefully controlled mixes—SFRC can approach strain-hardening behavior. While not common in standard mixes, this indicates the possibility for the material to carry increasing load even after initial cracking, a behavior more typical of ductile materials. This is especially relevant in applications involving dynamic loads, such as industrial flooring subject to cyclic forklift traffic or tunnel linings exposed to ground movement.

Industry standards such as the BS EN 14651 flexural beam test quantify this behavior by measuring residual strength at various crack mouth opening displacements. Higher residual strengths indicate more robust post-crack performance, directly correlating with the quality of fiber anchorage and distribution within the mix. These metrics allow engineers to specify SFRC not merely as an additive but as a quantifiable structural component.

Yet, it’s important to recognize that achieving optimal behavior hinges on proper mix design. Too many fibers can reduce workability and cause clumping; too few yield marginal benefits. Understanding these relationships empowers designers to tailor SFRC to the demands of each project, ensuring predictable and reliable performance.

Reducing Rebar Requirements and Enhancing Structural Behavior

One of the most transformative implications of steel fiber use is its potential to reduce—and in some applications partially replace—traditional reinforcing steel. Mandalawi commented that concrete’s natural tensile strength is minimal, but “this contribution from the steel fiber completes the strength diagram.” In essence, if fibers can carry part of the tensile load and control crack development, the structure no longer relies exclusively on rebar to maintain equilibrium or serviceability. This does not mean eliminating rebar entirely; rather, it enables hybrid reinforcement strategies where fibers handle distributed tensile stresses and rebar handles peak structural demands.

Real-world applications increasingly demonstrate the viability of this approach. In raft foundations, basements, retaining walls, and large-format slabs, hybrid SFRC systems have reduced rebar requirements by 30–50% while maintaining or improving structural performance. One example cited by Mandalawi involved loads as high as 2,500 kN; by integrating fibers with a reduced rebar layout, the project achieved a 50% reduction in reinforcement and 36% reduction in carbon emissions, all while accelerating construction and improving site conditions.

“Imagine that you have… a very clean, very fast process. You are making a sustainable solution, cutting 50% in CO₂,” he added.

These improvements hinge on SFRC’s ability to control crack widths more effectively than conventional reinforcement alone. By limiting crack propagation, the structure maintains stiffness, reduces long-term maintenance needs, and improves durability under aggressive conditions. However, code limitations remain: many standards do not yet fully account for SFRC’s shear capacity or long-term behavior in highly loaded structural elements. Until regulations evolve, hybrid systems offer a balanced path forward—reducing material use and environmental impact while maintaining engineer and regulator confidence.