Do the antimicrobial properties found in Copper fight bacteria and deadly viruses, including COVID-19? Studies show that it is a warrior metal, but to what extent? In this interview with Italian firm De Castelli, we learn about their project that could bring copper back to the front line of product manufacturing.

Italian metal manufacturer De Castelli has been well-known in creating furniture, fixtures and designer objects using solid copper, the first and currently the only antimicrobial metal surface approved by the US Environmental Protection Agency (EPA).

Copper has a self-sterilizing surface that requires neither electrical or chemical cleaners which makes it an ideal material that can prevent viruses from infecting users who touch its surface. Studies have shown that coronavirus survives on copper for 4 hours, compared to other metals or materials like plastic and stainless steel where it remains at a long duration of 3 to 5 days. Copper has also been observed to degrade the viruses that settle on its surface, according to the study made by scientists from the University of Southampton.

In light of COVID-19, the firm has started a project that might bring copper back to the fore as the main material used in constructing furniture, fixtures and structures for public spaces, healthcare facilities, offices and retail spaces.

In collaboration with university researchers, De Castelli is studying how to preserve the antimicrobial properties of copper by developing a production method that will be capable of eliminating the need for any surface treatment on copper and maintain its chromatic effects.

In an email correspondence with CEO Albino Celato, we learned about how the company’s research and development department is involved in experimenting with copper, with projected results to be ready in Autumn 2020.

ArchiExpo e-Magazine: Can you tell us about the project?

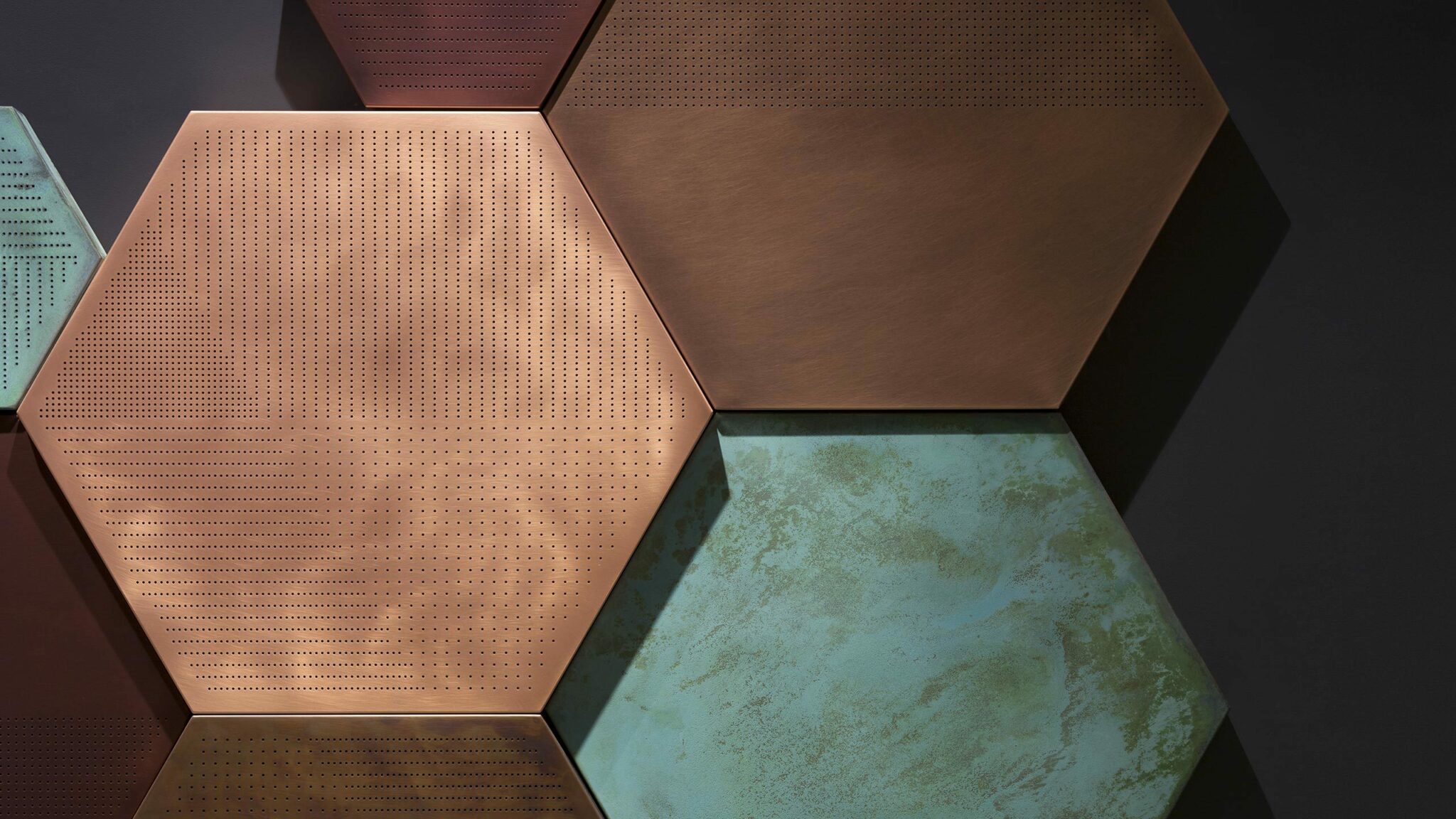

Albino Celato: The project is at its very first stage. Up to now, we have always preferred the aesthetic aspects of copper by researching and deepening shades and finishes obtainable through oxidation and handcrafted processes instead of bringing to light intrinsic features of copper – such as antimicrobial properties and conductivity – that have always been known.

ArchiExpo e-Magazine: Can you tell us more about your experiment on copper?

Albino Celato: At the moment, the focus is on finding out possible handcrafted finishing that can keep intact the intrinsic antibacterial properties of copper and offer high-ended aesthetic results at the same time. It is therefore a matter of avoiding varnishes, oils, or waxes that alternate its properties and enhancing the copper naturalness and ability to change under the action of time. We will then ask for university researchers or institutes to endorse the solutions we are finding out.

ArchiExpo e-Magazine: What is the main objective of this experiment/ project on copper for De Castelli?

Albino Celato: The aim is to make a synthesis between functionality and aesthetics starting from a reflection on the intrinsic properties of the raw material in order to offer products, surfaces or custom projects not only pleasing from the aesthetic point of view but also capable of helping to reduce the probability of permanence of bacteria.

ArchiExpo e-Magazine: Do you have some pieces in your present collection that are already made with antimicrobial copper? If there are, can you share them with us and how you designed and built each piece?

Albino Celato: We are starting now to develop new finishing that keeps intact the antimicrobial properties. The first products will be ready in Autumn 2020.

ArchiExpo e-Magazine: Your company has developed new surface solutions for many years. Can you share with us some recent copper finishes that you have done and which collection or furniture piece is made with your new copper finish?

Albino Celato: The craftsmanship of copper, as well as brass, iron, and steel, is the DNA of De Castelli, inherited by four generations of masters in the art of ironwork. We are therefore accustomed from our origins to handcraft copper in different shapes and sizes to obtain the most unusual results, from small to large scale. With copper, we realize pieces of furniture such as cabinets Marea, Polifemo, and Elizabeth or bookcases such as Talea. We also realize custom projects such as desks for receptions or bars, as well as special covering surfaces for floors and walls.